-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1982 Lada Niva

- Thread starter GoceKU

- Start date

- Joined

- Jul 14, 2017

- Messages

- 2,445

So the engine from this:

View attachment 336609

could bolt onto this:

View attachment 336610

who would have thought????

-brino

Yeah, at the time it was the best small diesel engine

Can you see the similarity.

- Joined

- Jul 14, 2017

- Messages

- 2,445

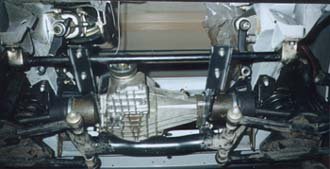

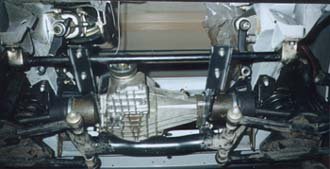

Weekend is upon us so i have some free time, so i spent some of it working on the Little Niva. Took the hood off, took the front section of the exhaust, took off the the front metal shields, removed some of the wiring just to protect it and make more room. I need to disassemble the front suspension, so i can pull the front driveshafts and make mounts for the front diff, also i've been told i should make shield for the diff. It's a very strange way the diff is mounted, is bolted with 3 bolts straight to the engine, can't imagine the movement of the engine when it torques is good for the axles or the driveshaft.

- Joined

- Jul 14, 2017

- Messages

- 2,445

- Joined

- Jul 14, 2017

- Messages

- 2,445

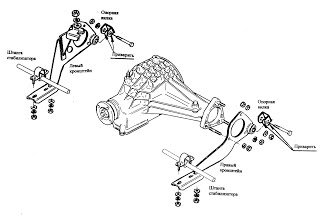

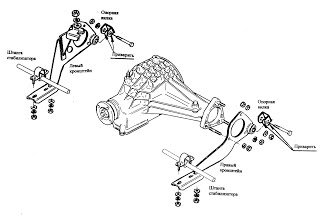

I've looked at others designs for mounting the front diff independently from the engine, mounting the front at the inner cv joints is no brainer, but at the back where the driveshaft bolts up there is no good place to bolt it to. Having the front mounts go all the way back may be a good solution but as memory serves there is where the exhaust passes thru. I've searched online how to properly support a front diff but there is nothing. Any advice or experience, if a support the front with two mounts should i run one or two also in the back, also how big or what size of rubber mounts to find and use to avoid noise and vibration inside, any thought is much appreciated.

- Joined

- Apr 23, 2018

- Messages

- 6,506

The differential mounts do not need to be very heavy to work. The only thing they need to do is locate the diff and prevent it from rotating under torque. If you drive in 2WD most of the time, that is even less duty for the mount.

The example you give uses the front sway bar as its main anchor. That is already decoupled from the frame by the sway bar bushings. You may want to soft mount the differential with rubber bushings and shoulder bolts that can be fully torqued in the diff case. Under 4x4 conditions, vibration would be coming from the driveshaft. The CV joints will run smooth on their own. You can look at the rubber isolation bushings on the transmission and transfer case to give you an idea about how much rubber is right for your differential. I don't think it will take much.

It is an interesting problem, so I am interested in seeing your solution!

The example you give uses the front sway bar as its main anchor. That is already decoupled from the frame by the sway bar bushings. You may want to soft mount the differential with rubber bushings and shoulder bolts that can be fully torqued in the diff case. Under 4x4 conditions, vibration would be coming from the driveshaft. The CV joints will run smooth on their own. You can look at the rubber isolation bushings on the transmission and transfer case to give you an idea about how much rubber is right for your differential. I don't think it will take much.

It is an interesting problem, so I am interested in seeing your solution!

- Joined

- Jul 14, 2017

- Messages

- 2,445

Last week has been very hectic so i haven't had any time to do any real work in the garages, but i had some time to think about which bushes to use to insulate the front diff on this little 4x4, i've decided on two 50mm solid rubber bushes for the front of the diff near the inner CV joints where most of the weight is located, and one or two 70mm torque style mount for the rear of the diff, back there there isn't much to mount to exept the anti roll bar. And i want to avoid mounting to it because i have future plans to modify it.

- Joined

- Jul 14, 2017

- Messages

- 2,445

Last few weeks have been incredibly busy for me at work. I've been using what spare time i have left to do some cleaning in the big garage. I've also done some work on the Little Niva, started taking apart the front suspension, and released i'll have to to drop the entire suspension, because the springs are in the way. That means i'll take this opportunity to change the suspension bushings, i also got me two rubber bushings for the front diff mounts, they are old but still good to use, they are made in yugoslavia so that dates them at least 30 years old. On a another front my new lada centre cap stickers arrived, i bought black ones with the new logo now, you can see the difference, compared to the silver ones i used on the sprinter wheels. That motivated me to do the work left to finish those wheels, to fix the corrosion around the centre caps. I sanded down all the corrosion, then i apply some 2K gray primer, that i'll left it to dry and shrink down.

- Joined

- Jul 14, 2017

- Messages

- 2,445

Yesterday after work i stop by the steel place and bought me a piece of plate steel to make the diff mounts from. I also stop by a parts store and bought me an engine mount for a yugo new, and is also made in yugoslavia. This got me motivated to get things done, first part to come off was the passenger side suspension, i had to remove the spring to get the axle out, it will be a struggle to get them back in again. With the axle on a bench i removed the factory diff mount and oil seal plate. Then i did it all over again on the drivers side.