Now the chips are flying.

I don't have a reliable mill vice so I am using my dividing head as a angle block to provide a vertical surface and 3-2-1 blocks to keep things square. this also helps to keep the mill head nearer the table improving the rigidity of the machine.

First job was to square up the material for the cylinder head.

Then mill out the lower part of the head, ready for the serious work later

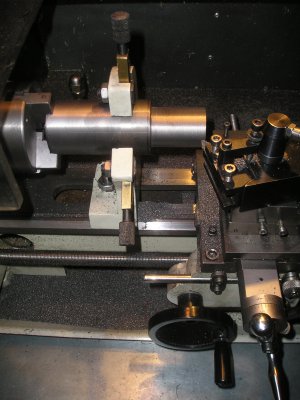

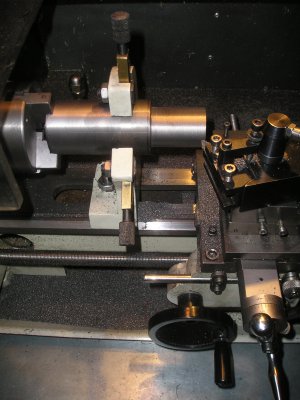

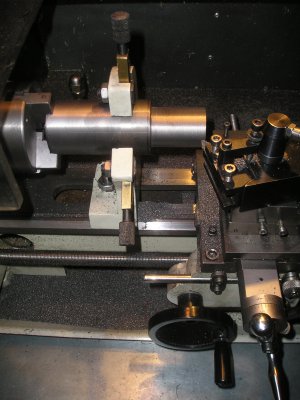

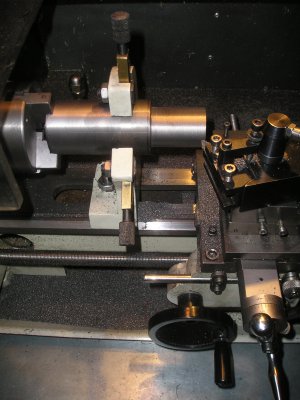

Then I set up the material for the liner and piston in the lathe, for similar treatment. at the moment I have kept the the piston blank attached, thinking that i may use the liner material as the chucking piece.

the other option is to mount the piston blank on a spigot to do the outside, then remove the spigot, and do the inside,???

We have visitors arriving tomorrow so work will be on hold for a few days.

Now I have to dig out the lathe from all those chip's.

Brian.