-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

5C Collet Drawbar

- Thread starter Chuck K

- Start date

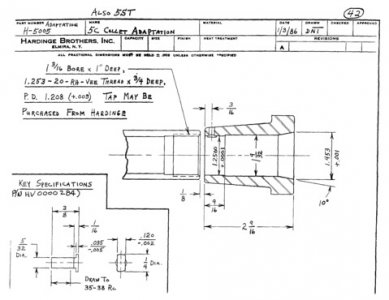

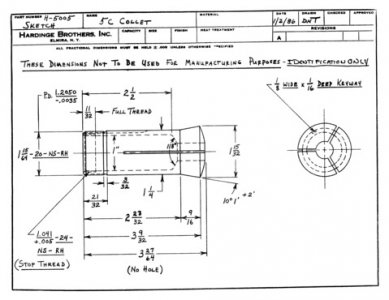

Hey I second your question on this one, I too have been trying to figure the major, and minor dimensions, so I can go inside the tube and machine a step for a safe stop spot! It’s easy to get the 1.25” spec's but the guys that did it that way, tell me it works but the collets are pretty loose, on the tube threads! Bob in OregonI'm planning on making a 5c drawbar for my lathe. I know the collet thread is 1.238-20. My question is what size hole do I bore for the threads. I've googled it and come up with nothing. ThanksChuck

I was measuring the OD of the threads on my collets today. I have a hodge podge of collets that I have acquired over the years. About 90 % of them are hardinge. I just used a regular mike over the top of the threads. The hardinge measure about .015 larger than the imports. Assuming you used the 1.250 threads, I would guess that the hardinge would probably fit alright, but the imports would be real loose. I've made them before and they turned out alright but I would like to start with the correct bore this time.

Chuck

Chuck

- Joined

- May 4, 2013

- Messages

- 249

The Machinery Handbook will have all of the formulas necessary for calculating the minor and major diameter of this thread. I was looking at this information the other day, as i too am planning on building a hand-wheel collet closet for my Heavy Ten. (Once I finish the rebuild)

The thread below has most of the information needed to make the calculations. But you will need to find the formulas themselves in the Machinery Handbook. If you don't have one, get one, even an old one. I find that it is the most used tool in my toolbox, I use it most every day I am in the shop. I don't have one handy here at work, but ill try to take a photo of the page when I get home.

http://www.hobby-machinist.com/show...Lathe-Question?p=135771&viewfull=1#post135771

Good luck!

-Cody

The thread below has most of the information needed to make the calculations. But you will need to find the formulas themselves in the Machinery Handbook. If you don't have one, get one, even an old one. I find that it is the most used tool in my toolbox, I use it most every day I am in the shop. I don't have one handy here at work, but ill try to take a photo of the page when I get home.

http://www.hobby-machinist.com/show...Lathe-Question?p=135771&viewfull=1#post135771

Good luck!

-Cody

4

4GSR

Forum Guest

Register Today

Machinerys handbook does not have the formulas for 60 deg vee threads. You have to extrapulate them from given information on threads that are the same pitch but different diameter. Formulas can only be found in the ASME-ANSI Specification B1.1 for screw threads. (Maybe an ISO specification by now).

In the down load section, there are several useful references on figuring thread parts including one that I've been using for many years now.

Ken

In the down load section, there are several useful references on figuring thread parts including one that I've been using for many years now.

Ken

Cody, I have the Machinery Handbook. I looked in it briefly for 5C collets and didn't find anything. I guess maybe I need to dig a little deeper. It seems to me that when I cut threads, the diameter grows somewhat. That's why I don't want to go with just the major and minor diameters. (not sure which is major or minor when talking about internal threads) I don't know if I'm explaining this well, but it would seem that I need to bore the hole a bit larger to accommodate the growth in the threads.

Chuck

Chuck

- Joined

- May 4, 2013

- Messages

- 249

The formulas that I am speaking of are for threading in general. The threads are a standard 60deg thread form, but on a non-standard diameter. Look in the Threading section, under 60deg sharp threads. There are a series of measurements and formulas for calculating the thread depth, major and minor diameters, etc, based on the pitch diameter, which in this case is 1.238". If I had mine handy, I would photograph the page, or give you the page number.

If you don't find it before I get home, I'll post it.

-Cody

EDIT:

The Machinery handbook should also have dimensions for a 5C collet, and various other collets as well. I was just looking at the page the other day, to determine the angle of the taper.

If you don't find it before I get home, I'll post it.

-Cody

EDIT:

The Machinery handbook should also have dimensions for a 5C collet, and various other collets as well. I was just looking at the page the other day, to determine the angle of the taper.

4

4GSR

Forum Guest

Register Today