- Joined

- Apr 30, 2015

- Messages

- 11,283

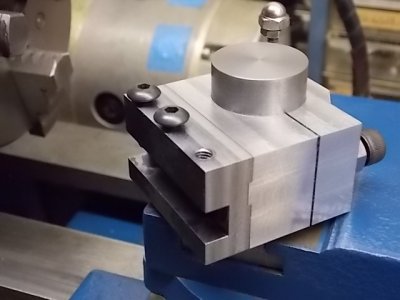

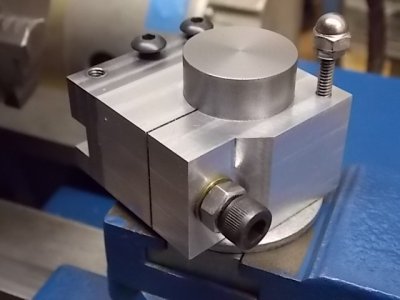

This took me about a week, amazingly no major goofs. My lathe has been bugging me to do it for a while- good catch-up project for pandemic boy

I used 1" cold rolled for the post instead of the more usual 1-1/4", seems pretty solid to me. That was the only piece I needed to buy.

I'm going to fix the socket head screw with removable Loctite, then use the nut to do the pinching- an open end wrench just slips over

-Mark

Next project: A knurler

I used 1" cold rolled for the post instead of the more usual 1-1/4", seems pretty solid to me. That was the only piece I needed to buy.

I'm going to fix the socket head screw with removable Loctite, then use the nut to do the pinching- an open end wrench just slips over

-Mark

Next project: A knurler

Attachments

Last edited: