- Joined

- Jan 21, 2015

- Messages

- 67

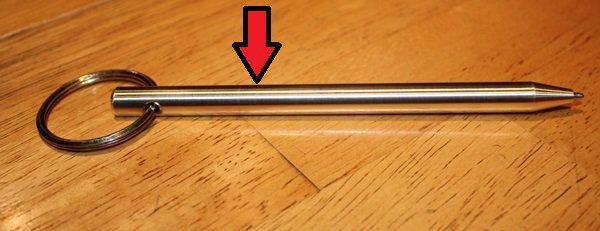

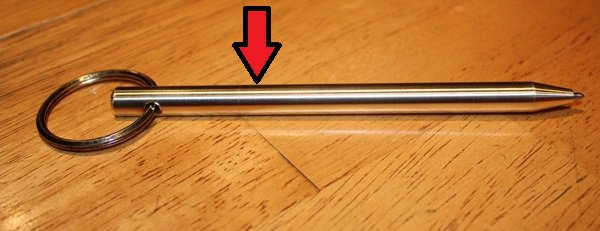

I owed a guy a favor, so since I had set up to make one pen for my wife, I thought I'd make a second as a gift. This is another 2-piece, screw-together, ballpoint pen. This one is all brass (my last one was brass/aluminum), and even though it is a mere 5.5 inches long, it is a heavy bastard. This one also takes a Fisher Space Pen refill so it writes upside down.

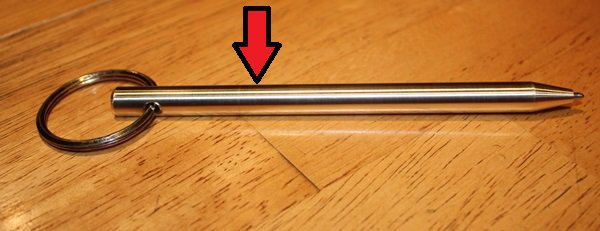

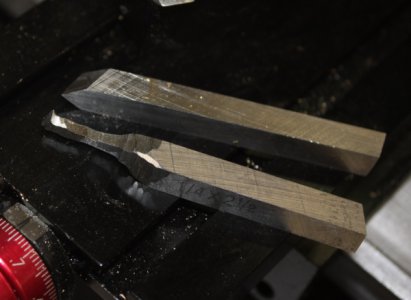

If it looks like it is sitting crooked on the table, that's because I milled a long tapering flat on one side. This prevents rolling (if the owner wants to remove the ring). But it keeps the barrel completely round down where sensitive fingertips grip it. Here's a pic of the milling:

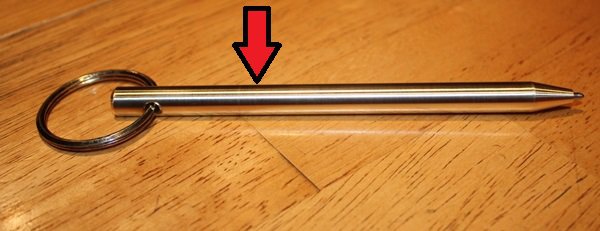

Notice that on this piece, the 2 screw together halves are hard to distinguish, the seam is pretty smooth. I milled notches before drilling through, so the holes would have a nice edge. Here's a detail of the end (notice the 'flat tire' effect of the flattened side):

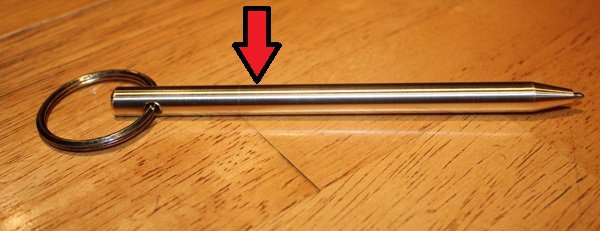

Once again, I used my hand-made (by eye!) threading tools to make matching 0.5mm pitch (51 tpi) threads. Look how nice that high-leaded brass cuts:

I believe I am done with pens, and I will move on to smaller and smaller projects as I try to get down to pocketwatch scale. My lifetime goal is to build a pocketwatch, so back to work.

If it looks like it is sitting crooked on the table, that's because I milled a long tapering flat on one side. This prevents rolling (if the owner wants to remove the ring). But it keeps the barrel completely round down where sensitive fingertips grip it. Here's a pic of the milling:

Notice that on this piece, the 2 screw together halves are hard to distinguish, the seam is pretty smooth. I milled notches before drilling through, so the holes would have a nice edge. Here's a detail of the end (notice the 'flat tire' effect of the flattened side):

Once again, I used my hand-made (by eye!) threading tools to make matching 0.5mm pitch (51 tpi) threads. Look how nice that high-leaded brass cuts:

I believe I am done with pens, and I will move on to smaller and smaller projects as I try to get down to pocketwatch scale. My lifetime goal is to build a pocketwatch, so back to work.