- Joined

- Feb 7, 2013

- Messages

- 792

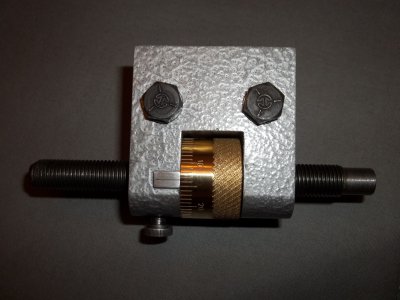

Hi I am new to the forum I have made some modifications to my 10 inch atlas lathe I thought I might start a new thread. Here it a picture of the new crossfeed screw mount it has double bearing's the nut on the end sets the pre load and the dial is a direct read dial that floats freely. The stock one use's the dial for preload and tightens up under load. The new mount tightens up with a spanner wrench under the dial.. Ray