In some forums, big pics are a problem, so I started conservative. Here it is max res,' large'

I see what you mean by Z, that might explain the flat vise, which I'd wondered about

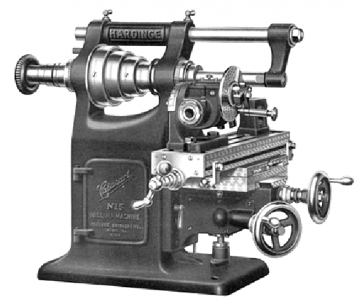

but it will drop a couple of inches... and the quill is dropped all the way down. I see what uou mean about horizontal - it looks like the Hardinge part was a horizontal mill.

I see what you mean by Z, that might explain the flat vise, which I'd wondered about

but it will drop a couple of inches... and the quill is dropped all the way down. I see what uou mean about horizontal - it looks like the Hardinge part was a horizontal mill.