W

WMello

Forum Guest

Register Today

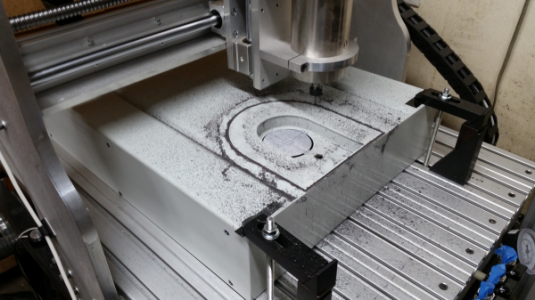

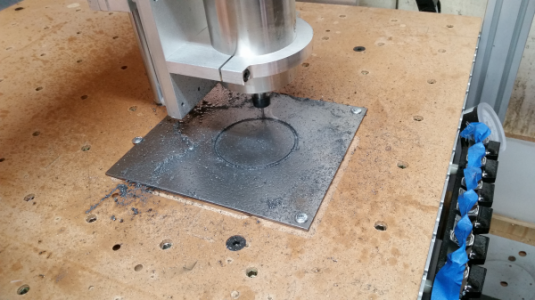

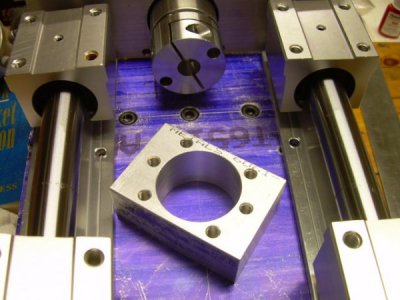

This is about a project done back in 2012.

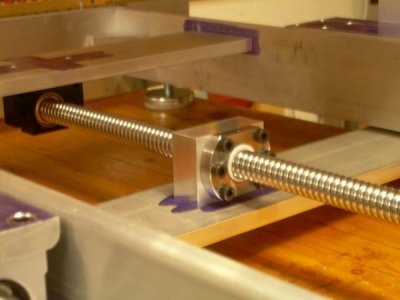

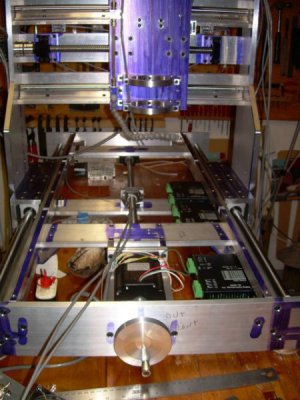

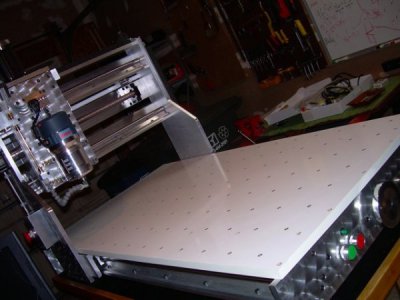

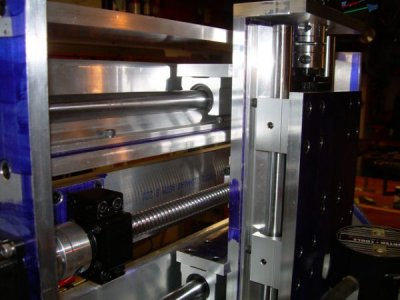

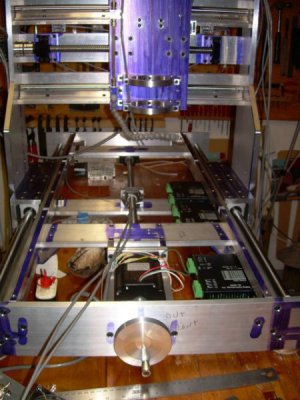

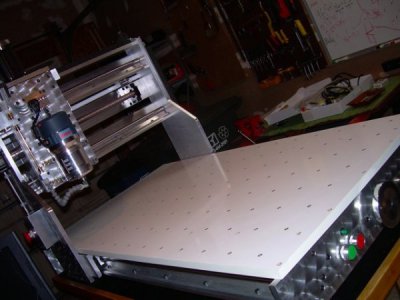

It's a CNC Router of my own design and built, based on data collected on the internet from others builders.

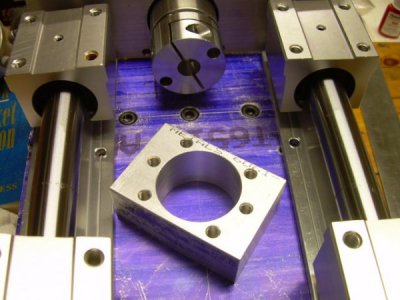

It was designed primary to cut wood, so it uses a router as spindle; but I've been cutting aluminum and brass successfully. Several parts of the Clock project I'm working on were made on this machine.

Brino, on this forum, asked about it; so I've collected some old information and here it is:

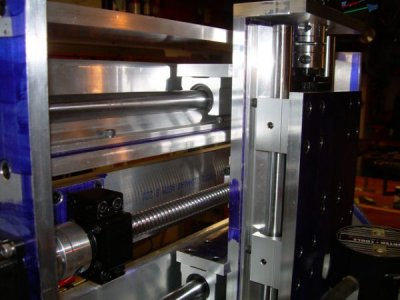

It was made basically out of 1/2 aluminum 6061 flat and L stock.

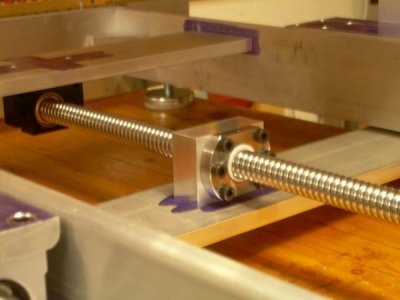

20mm Ball screws rails and nuts acquired via eBay from user solar-jean (from china)

Motors, controllers and components from Automation Technologies, UgraCnc, Cnc4Pc and other suppliers. McMaster of course.

Stepper motors:

KL34H2120-60-4B Nema 34 1200 Oz/in for the X axis

KL23H2100-50-4B Nema 23 570 Oz/in for the X axis

Controllers: KL-6050

Spindle: Bosch 1617 router

It is run by Mach3, gCode from CamBam

Some pictures:

Wagner

It's a CNC Router of my own design and built, based on data collected on the internet from others builders.

It was designed primary to cut wood, so it uses a router as spindle; but I've been cutting aluminum and brass successfully. Several parts of the Clock project I'm working on were made on this machine.

Brino, on this forum, asked about it; so I've collected some old information and here it is:

It was made basically out of 1/2 aluminum 6061 flat and L stock.

20mm Ball screws rails and nuts acquired via eBay from user solar-jean (from china)

Motors, controllers and components from Automation Technologies, UgraCnc, Cnc4Pc and other suppliers. McMaster of course.

Stepper motors:

KL34H2120-60-4B Nema 34 1200 Oz/in for the X axis

KL23H2100-50-4B Nema 23 570 Oz/in for the X axis

Controllers: KL-6050

Spindle: Bosch 1617 router

It is run by Mach3, gCode from CamBam

Some pictures:

Wagner