B

BRIAN

Forum Guest

Register Today

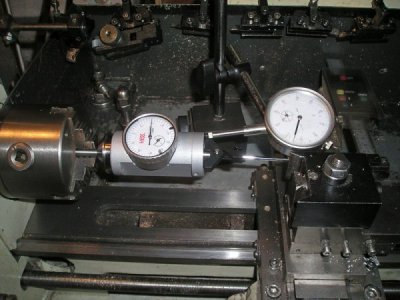

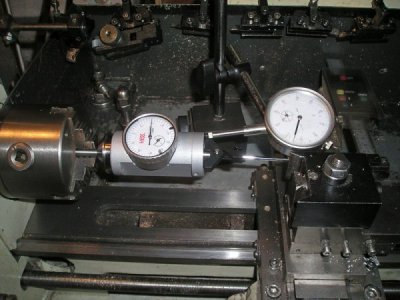

Just lately I have had cause to question the accuracy of my coaxial indicator. so as a test I held the stem in the lathe 3 jaw. and placed the end of the short feeler ( the most accurate ) against the tool post zeroed the indicator -- the cross slide dial and the digital read out. fed in the cros slide to give one division on the Co ax -- said to be .0005" offset,

And the dial and digital read out read about .0025" this did not look good. so to get better accuracy I went to 10 divisions and divided the result by 10 and came up with .0027"per div the long feeler gave a figure of.0064" per div.

The information with the indicator defiantly says :0005" per div offset.

So confused and just a bit annoyed I placed a dial indicator against the body of the co ax and lo and behold one division on the co ax is .0005" on the indicator. IT's the dial resolution not the indicator.

How is that for a useless piece of information??

The manufacturers have forgotten about the ratio of the feeler arm. Test yours you may be surprised.

I am waiting for a reply from the suppliers

Brian is not a happy boy.

And the dial and digital read out read about .0025" this did not look good. so to get better accuracy I went to 10 divisions and divided the result by 10 and came up with .0027"per div the long feeler gave a figure of.0064" per div.

The information with the indicator defiantly says :0005" per div offset.

So confused and just a bit annoyed I placed a dial indicator against the body of the co ax and lo and behold one division on the co ax is .0005" on the indicator. IT's the dial resolution not the indicator.

How is that for a useless piece of information??

The manufacturers have forgotten about the ratio of the feeler arm. Test yours you may be surprised.

I am waiting for a reply from the suppliers

Brian is not a happy boy.

Last edited by a moderator: