- Joined

- Aug 29, 2016

- Messages

- 15

Browsing through other forum sections, it seems most folks poo-poo the lathe/mill (/drill?) combo machines as being the very definition of compromise -- terrible at all 3 tasks. The main advantage is space savings but also there is some cost benefit.

Anyway, as someone with limited space, how bad are these machines really?

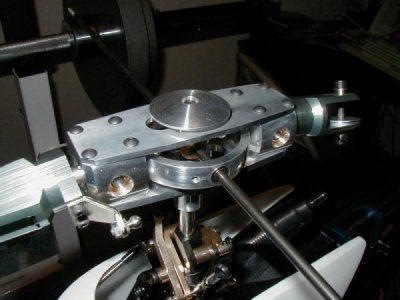

ISTM the lathe component is exactly the same as the standalone machine. In fact many manufacturers just have a kit that adapts one of their existing mill columns to one of their existing lathes.

For the mill component, are you giving up a significant amount of rigidity afforded by the base of the standalone version of the mill vs mounting it to the carriage? It doesn't seem so given that this class of mill is pretty "lightweight" to begin with.

Anyway, as someone with limited space, how bad are these machines really?

ISTM the lathe component is exactly the same as the standalone machine. In fact many manufacturers just have a kit that adapts one of their existing mill columns to one of their existing lathes.

For the mill component, are you giving up a significant amount of rigidity afforded by the base of the standalone version of the mill vs mounting it to the carriage? It doesn't seem so given that this class of mill is pretty "lightweight" to begin with.