- Joined

- May 27, 2016

- Messages

- 3,469

It seems that first clean-up easily leads to fix-it-up addiction.

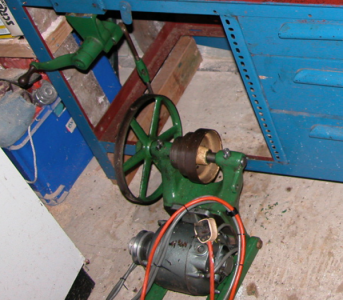

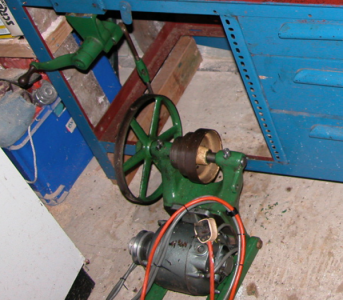

The South Bend 9c, acquired unexpectedly at a crazy bargain price, has things going on in the drive countershaft.

I took this bit apart, because the previous owner had "re-arranged" things to mount it upside down on a piece of 2" x 4" wood fixed to the floor instead of bolting it to the underside of the bench. This required the 3-speed pulley to be mounted on the shaft the turned to be the other way about. I think the oil-wick cups ended up upside down also. Probably it has seen some running without proper oiling.

1) I could just put it all back, as it is, but properly, and hope the present condition is not going to deteriorate in accelerated fashion. Does this wear matter much? Can I ignore it?

2) Replace it? It is a piece of 7/8" steel with a taper pin hole through it.

In the picture, I have positioned it somewhat as it should be if it were mounted up under the tailstock, as per the SB drawings, with oil wick cups facing upwards. The larger belt pulley is supposed to be toward the spoked wheel, with the small end to the right, to suit the pulley on the headstock.

The condition of the cast iron shaft journals is also a bit scored, just like the shaft.

There is an obvious "Catch-22" in trying to turn anything, but 7/8" is maybe very available standard stock, even if the ends were just hacksawed. The problem is, I have no idea what it takes to make a taper-pin hole.

The South Bend 9c, acquired unexpectedly at a crazy bargain price, has things going on in the drive countershaft.

I took this bit apart, because the previous owner had "re-arranged" things to mount it upside down on a piece of 2" x 4" wood fixed to the floor instead of bolting it to the underside of the bench. This required the 3-speed pulley to be mounted on the shaft the turned to be the other way about. I think the oil-wick cups ended up upside down also. Probably it has seen some running without proper oiling.

1) I could just put it all back, as it is, but properly, and hope the present condition is not going to deteriorate in accelerated fashion. Does this wear matter much? Can I ignore it?

2) Replace it? It is a piece of 7/8" steel with a taper pin hole through it.

In the picture, I have positioned it somewhat as it should be if it were mounted up under the tailstock, as per the SB drawings, with oil wick cups facing upwards. The larger belt pulley is supposed to be toward the spoked wheel, with the small end to the right, to suit the pulley on the headstock.

The condition of the cast iron shaft journals is also a bit scored, just like the shaft.

There is an obvious "Catch-22" in trying to turn anything, but 7/8" is maybe very available standard stock, even if the ends were just hacksawed. The problem is, I have no idea what it takes to make a taper-pin hole.