- Joined

- Nov 8, 2012

- Messages

- 783

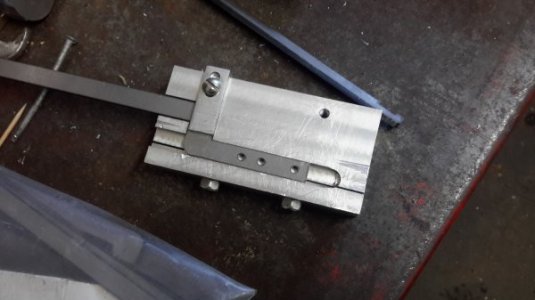

I'm trying to help out a friend of mine with a shotgun pump slide.

As you can hopefully see in the pictures, the slide is machined with a concave on the short end to mesh with the tube. There is a small nib left on the end of the slide that fits in the tube slot and is then riveted to the tube.

The long end of the slide is long enough it prevents me from getting at it with a boring bar while keeping mill head parallel to the slide. Can't get to it from the other end due to needing to leave a nib.

I considered using a straight or she'll mill cutter, but can't seem to find one the right size.

As you can see, the tube is just a hair over 1" in diameter and I can't find a 1" cutter. I'm considering trying either a T-slot cutter or a keyway cutter, but wasn't sure how well it would work.

Any ideas or suggestions ???

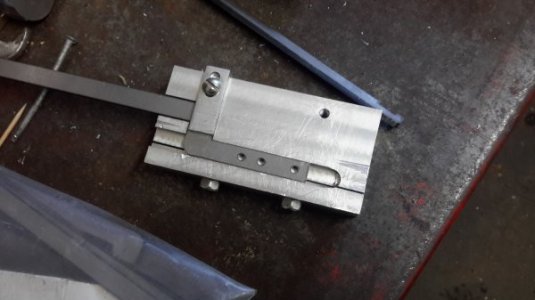

As you can hopefully see in the pictures, the slide is machined with a concave on the short end to mesh with the tube. There is a small nib left on the end of the slide that fits in the tube slot and is then riveted to the tube.

The long end of the slide is long enough it prevents me from getting at it with a boring bar while keeping mill head parallel to the slide. Can't get to it from the other end due to needing to leave a nib.

I considered using a straight or she'll mill cutter, but can't seem to find one the right size.

As you can see, the tube is just a hair over 1" in diameter and I can't find a 1" cutter. I'm considering trying either a T-slot cutter or a keyway cutter, but wasn't sure how well it would work.

Any ideas or suggestions ???