- Joined

- Dec 29, 2012

- Messages

- 72

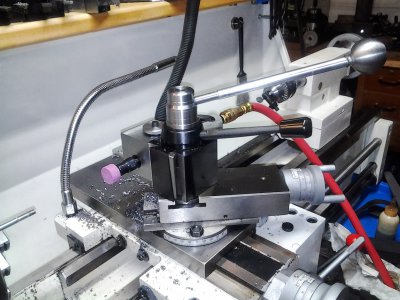

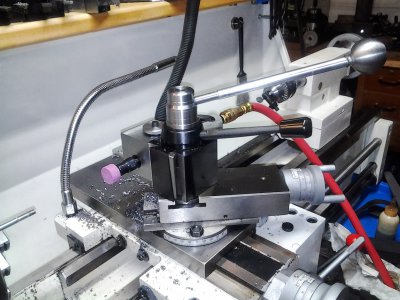

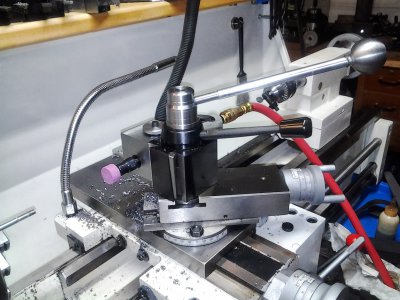

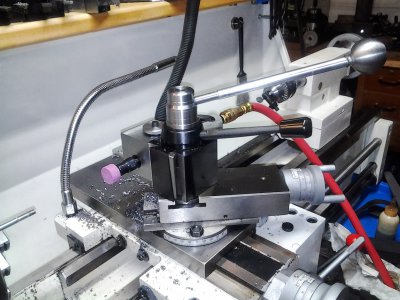

Been working on this for three days. No plans or anything But started out as 2 1/4" square steel from my neighbors salvage yard. I used a homemade dovetail cutter made from a 3/8th" carbide lathe bit similar to a fly cutter. Made for BXA QCTP for my PM1236.

I also made the topnut and for the handle for the QCTP.

Bob

I also made the topnut and for the handle for the QCTP.

Bob