- Joined

- Dec 3, 2013

- Messages

- 1,844

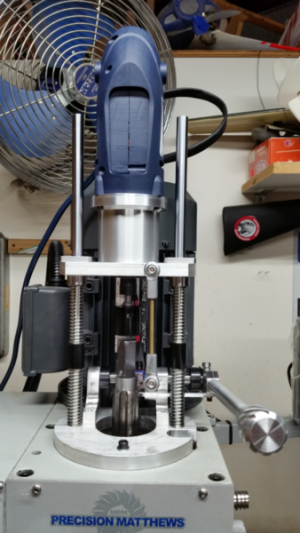

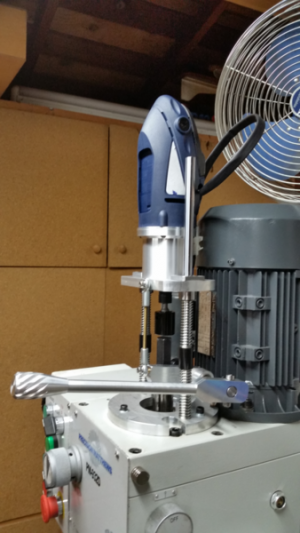

I recently picked up a heavy duty drill press with an R8 spindle and being spoiled with the pneumatic drawbar on my CNC mill I wanted to put one on the drill press. I don't care for the pneumatic impact wrench designs plus I don't want to run air to the machine.

I looked at various ideas for an electric drawbar from stepper motors with planetary gearboxes, AC gearmotors and electric impact wrenches. Wanting to keep it simple I decided on the electric impact wrench. There are a few examplesout on the interweb using cordless impact wrenches an the cheap HF 1/2 impact wrench.

After some searching I came across a 1/4" drive corded electric for dirt cheap and figured I would give it go if it had enough power for the job.

These must be overstock or refurbished since the label was removed. The manual says the brand is Mastercraft.

Fortunately it comes with a 3/4" socket and adapter. These are the parts I will use. I tried it as is and it has plenty of power for the job.

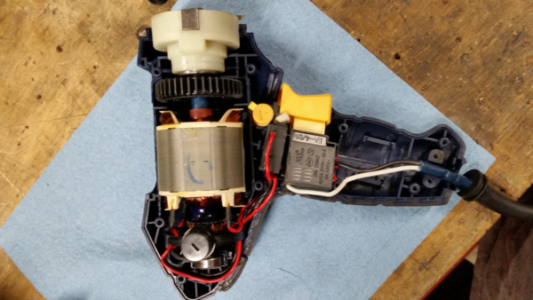

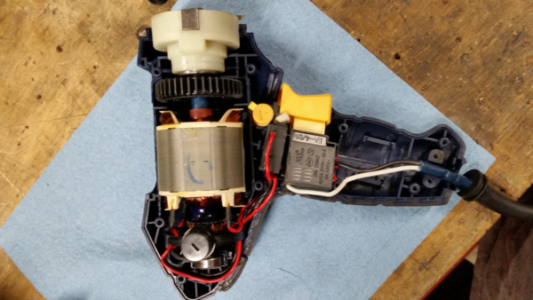

First order of business is to figure out how to mount it. After pulling the nose and removing the impact assembly I took measurements as best I could and decided to try and turn a flat on the nose to bolt to.

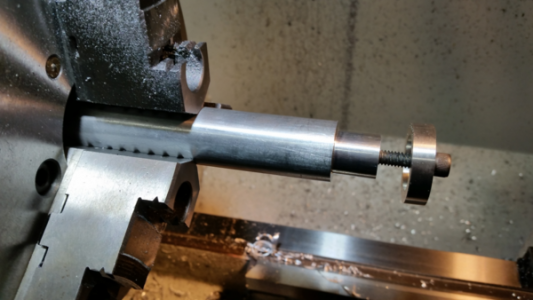

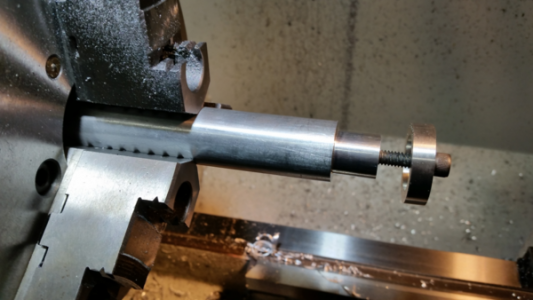

I made a simple mandrel to hold the nose and turned a minimal flat.

As it turned out the casting is very thin and after turning there was not enough material to thread to. There is not much room inside so using a nut was not an option.

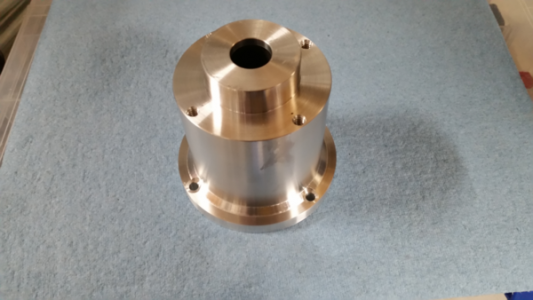

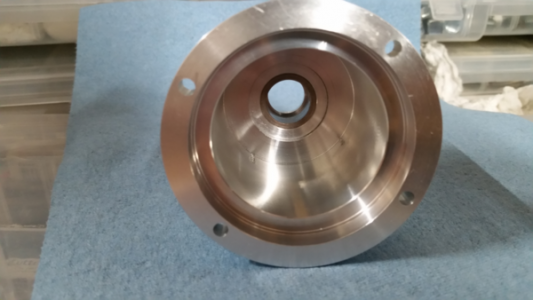

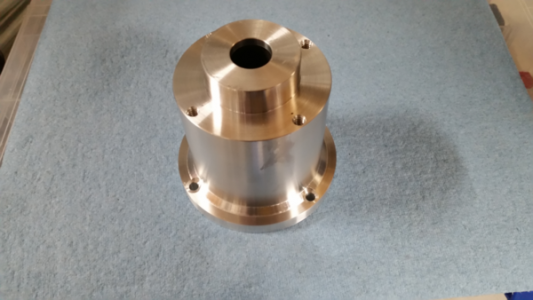

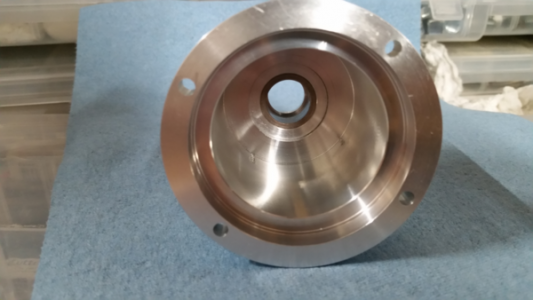

The only alternative was to remove the steel bushing and turn a new nose piece.

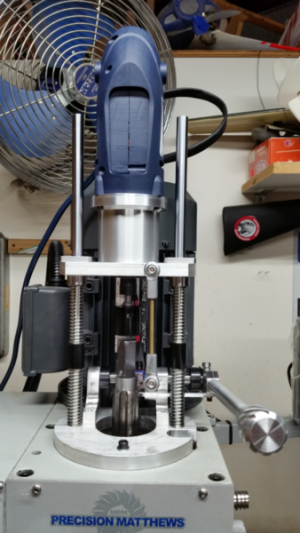

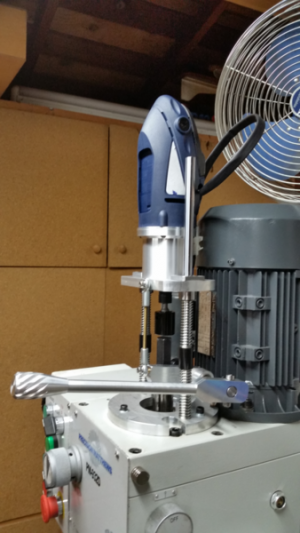

The rest of the assembly is similar to others with the exception that I made a lever assembly to raise and lower. On-Off & FWD/REV are achieved by pulling down on the handle and pushing left or right for forward and reverse. The factory trigger and FWD/REV switch are not used and the handle is cut off for clearance.

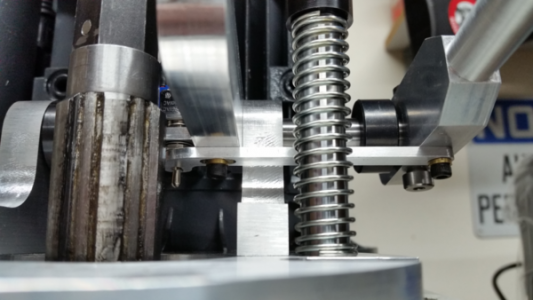

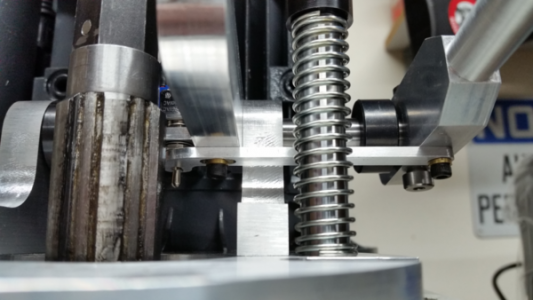

Here is a closeup of the switch and linkage. The switch is a DPDT On-Off-On momentary mini toggle. The motor is rated at 3.5A and the toggle switch is 6A so I think it should be okay. The lever arm self centers to the off position by a spring plunger and detent. The switch mount is machined as part of the linkage lever.

I looked at various ideas for an electric drawbar from stepper motors with planetary gearboxes, AC gearmotors and electric impact wrenches. Wanting to keep it simple I decided on the electric impact wrench. There are a few examplesout on the interweb using cordless impact wrenches an the cheap HF 1/2 impact wrench.

After some searching I came across a 1/4" drive corded electric for dirt cheap and figured I would give it go if it had enough power for the job.

These must be overstock or refurbished since the label was removed. The manual says the brand is Mastercraft.

Fortunately it comes with a 3/4" socket and adapter. These are the parts I will use. I tried it as is and it has plenty of power for the job.

First order of business is to figure out how to mount it. After pulling the nose and removing the impact assembly I took measurements as best I could and decided to try and turn a flat on the nose to bolt to.

I made a simple mandrel to hold the nose and turned a minimal flat.

As it turned out the casting is very thin and after turning there was not enough material to thread to. There is not much room inside so using a nut was not an option.

The only alternative was to remove the steel bushing and turn a new nose piece.

The rest of the assembly is similar to others with the exception that I made a lever assembly to raise and lower. On-Off & FWD/REV are achieved by pulling down on the handle and pushing left or right for forward and reverse. The factory trigger and FWD/REV switch are not used and the handle is cut off for clearance.

Here is a closeup of the switch and linkage. The switch is a DPDT On-Off-On momentary mini toggle. The motor is rated at 3.5A and the toggle switch is 6A so I think it should be okay. The lever arm self centers to the off position by a spring plunger and detent. The switch mount is machined as part of the linkage lever.