- Joined

- Sep 28, 2013

- Messages

- 4,306

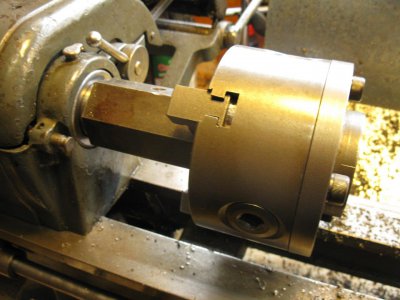

thought this might be useful, especially with an extra special ingredient - hex stock for the chuck body! That way I can also use it to cut flats on the mill

This was partly inspired by the one on deans photographica website, which is a rich source of project info. Especially useful were the gears needed to cut a 1.5mm pitch thread. http://www.deansphotographica.com/machining/atlas/ER25/ER25.html

stock left over from cutting of the piece I needed

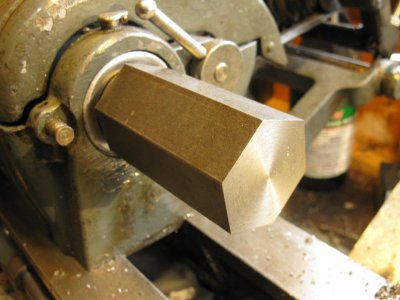

sawn end faced off. Lots of really light cuts with this much stick out and interrupted cuts

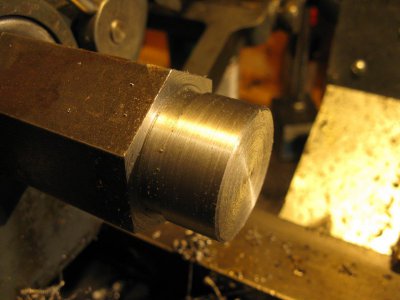

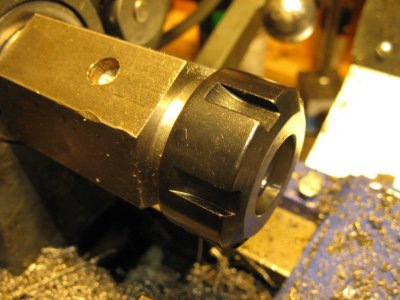

spindle hole drilled and bored out, with spindle register and threading relief (you can just see it at the back) cut ready for threading

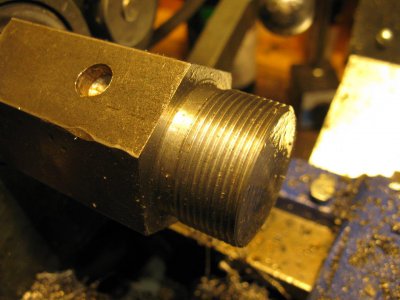

threading done I'm still amazed when this works out!

I'm still amazed when this works out!

This was partly inspired by the one on deans photographica website, which is a rich source of project info. Especially useful were the gears needed to cut a 1.5mm pitch thread. http://www.deansphotographica.com/machining/atlas/ER25/ER25.html

stock left over from cutting of the piece I needed

sawn end faced off. Lots of really light cuts with this much stick out and interrupted cuts

spindle hole drilled and bored out, with spindle register and threading relief (you can just see it at the back) cut ready for threading

threading done

Last edited by a moderator: