- Joined

- Oct 14, 2014

- Messages

- 1,970

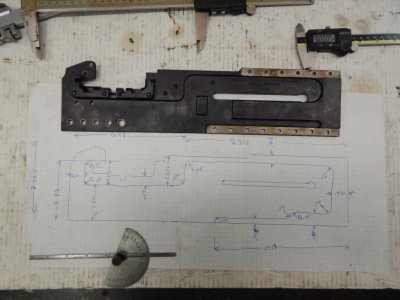

First a bit of background.

It common for the militaries of the world to sell their small arms when they are surplus to their needs. They can be imported to the USA if dis-assembled and the receiver is destroyed. At this point it is called a parts kit. These kits are available for a great many weapons. US law requires the weapon to only be built as a semi auto NOT full auto weapon.

The FN32 is perhaps the finest example of the John Moses Browning machine gun. Only about 60 kits were imported to the USA from Portugal. Learn more about building the very similar FN30 here:

http://browningmgs.com/FN/07_FN30build.htm

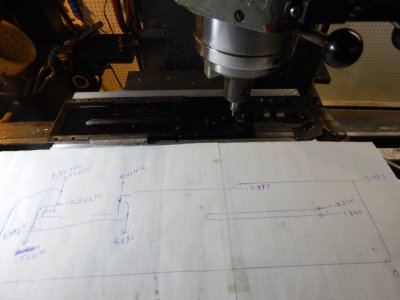

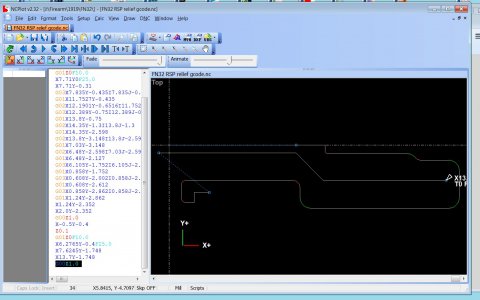

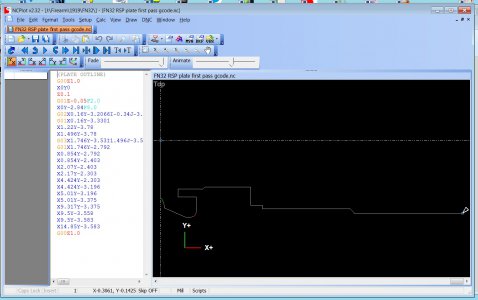

This thread covers CNC machining a new receiver or right side plate. Also posted at:

http://1919a4.com/showthread.php?54588-FN32-build

It common for the militaries of the world to sell their small arms when they are surplus to their needs. They can be imported to the USA if dis-assembled and the receiver is destroyed. At this point it is called a parts kit. These kits are available for a great many weapons. US law requires the weapon to only be built as a semi auto NOT full auto weapon.

The FN32 is perhaps the finest example of the John Moses Browning machine gun. Only about 60 kits were imported to the USA from Portugal. Learn more about building the very similar FN30 here:

http://browningmgs.com/FN/07_FN30build.htm

This thread covers CNC machining a new receiver or right side plate. Also posted at:

http://1919a4.com/showthread.php?54588-FN32-build

Steve Shannon, P.E.

Steve Shannon, P.E.