- Joined

- Feb 17, 2013

- Messages

- 4,406

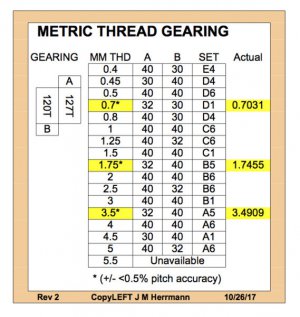

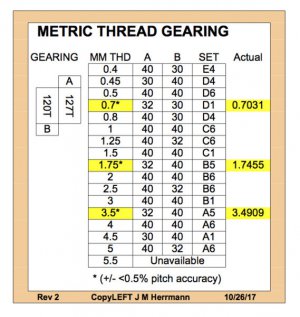

Some time back in 2014 I posted an "improved" metric threading chart for this series of lathes (including the 12x24 equivalents). The chart included all but one of the currently used metric threads (couldn't find a way to get 5.5mm pitch, used on M56 fasteners), and gave very close approximations to the 0.7, 1.75 and 3.5mm pitches (good within ½%). Today I found an alternate setup for the 0.7mm pitch (using a 46 tooth gear), and I wanted to verify it. Not having the lathe available, I revisited the entire calculation. In doing so, I noticed that I'd made two errors on my original chart. I've revised it accordingly, and double checked all the settings. Here it is: