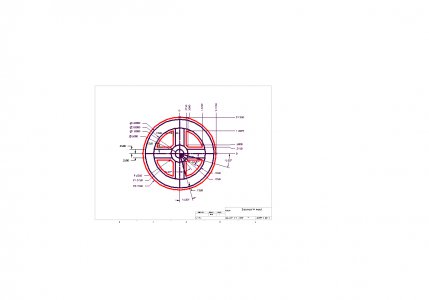

Here is the way that I would make the wheel.

Find the center of the rotary table with an edge finder or dial indicator mounted in the spindle. Set your x and y axis to zero at that point. If you do not have a DRO, you will have to account for any backlash in your lead screws. Mount your workpiece on the table so it centered on the rotary table. If you are going machine it all with the rotary table, the positioning is not as critical. I would put a sacrificial piece under the part so I could machine the entire thickness from one side.

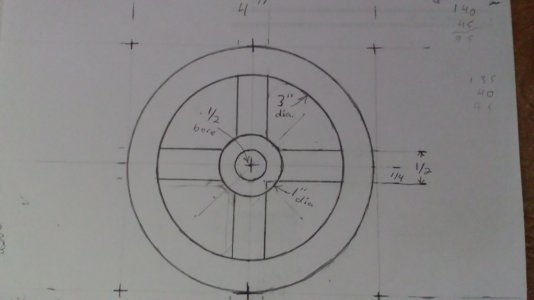

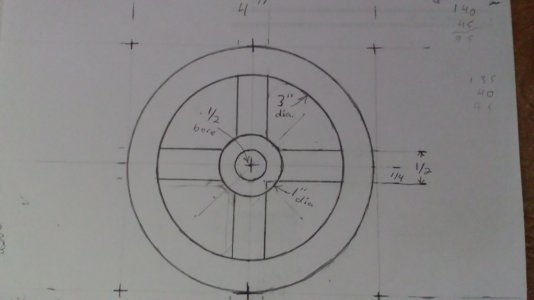

You can machine your bore by offsetting the x axis by the 1/2 the diameter of the bore minus 1/2 the diameter of the end mill. Likewise for the inner edge of the rim. You can machine the outer edge of the rim and hub by adding instead of subtracting your end mill diameter. Use the crank on your table to rotate it the full 360 degrees.

To cut the spokes, offset the y by 1/2 the width of the spoke plus 1/2 the width of the 3end mill and cut to intersect the outer edge of the hub and the inner edge of the rim. You will have to do some math here if you don't have CAD. If you have CAD you can pull the dimensions from the drawing. Since your spokes are recessed, you can machine to just short of touching the hub and rim by sight and clean up. This will profile one spoke.

Now rotate the table 90 degrees and cut the second spoke. Use the same x and y dimensions as before. Repeat for the remaining two.

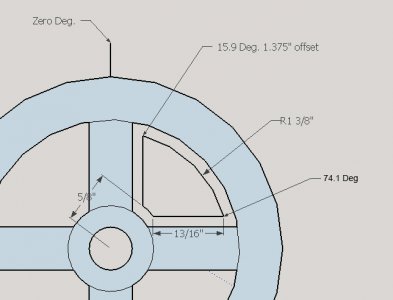

Now cut the arcs between the spokes by rotating the table. Again use some math or a CAD drawing to get the start and finish angles. When cutting the arcs, rotate the table to the start position with the tool path radius set on the x axis and the y axis set at zero. Rotate to the finish position to cut.

You will have to finish the recess on the reverse side by flipping the part and centering on the rotary table. Or you could mount it on a lathe and finish it that way.

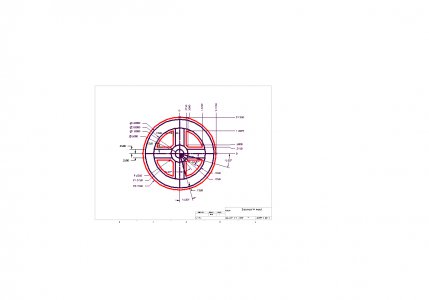

Here is a drawing of your part with dimensions Just remember that straight cuts are made with the x feed and curves are made with the rotary table feed. The 15.83 angle is 15 49' 36" and the 36.87 angle is 36 52' 12"