A

Alan H.

Forum Guest

Register Today

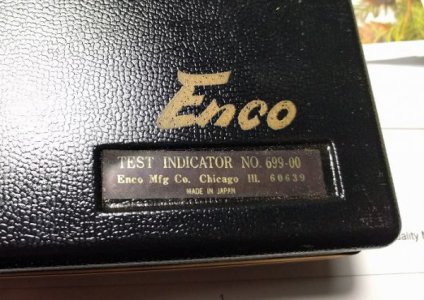

Looking to buy a Horizontal Test Indicator for setting/squaring the vise on my milling machine.

Looks like you can spend a little or you could spend a lot.

I want to buy once but also do not need to spend extra money for "brand/logo" on the face.

Is a 0.0005" graduation adequate? Of course the smaller you go gets you less range. This one gets you 30 thou range.

What is your experience?

Looks like you can spend a little or you could spend a lot.

I want to buy once but also do not need to spend extra money for "brand/logo" on the face.

Is a 0.0005" graduation adequate? Of course the smaller you go gets you less range. This one gets you 30 thou range.

What is your experience?