-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How To Use A Multimeter To Test

- Thread starter HMF

- Start date

Power or voltage?

Way too much to explain to the general question.

Checking what?

The short answer is read the instructions that came with the volt meter.

Next is Google "safe use of multi-meter".

If you are trying to check a specific thing then ask how to check power on a (describe thing here)

If you do not know how to use a multi meter do some reading first then practice with a battery or wall wart for voltage and a light bulb for resistance.

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

Way too much to explain to the general question.

Checking what?

The short answer is read the instructions that came with the volt meter.

Next is Google "safe use of multi-meter".

If you are trying to check a specific thing then ask how to check power on a (describe thing here)

If you do not know how to use a multi meter do some reading first then practice with a battery or wall wart for voltage and a light bulb for resistance.

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

- Joined

- Mar 19, 2014

- Messages

- 2,681

What kind of multimeter? What kind of power? The probes are typically insulated. Keep your fingers only on the insulated part. Set-up the meter correctly so you don’t smoke it. Very high voltage is a different animal/story.

- Joined

- Apr 12, 2011

- Messages

- 3,472

Here's a really good site that seems to cover the basics.

How to use a Multi-Meter

Might get you started.

How to use a Multi-Meter

Might get you started.

- Joined

- Apr 30, 2015

- Messages

- 11,280

Main idea is to set it to a range higher than what you are expecting to read, unless it is auto-ranging. Analog meters (with a needle) are often better for some tests like intermittants, and they are more rugged electrically than digital meters, important for sparky- motory type stuff.

Most cheap meters have poor probes/test leads, too short and with points not sharp enough to penetrate varnish and corrosion.

I like probes that can accept screw-on alligator clips, very handy and safer.

Mark S.

Most cheap meters have poor probes/test leads, too short and with points not sharp enough to penetrate varnish and corrosion.

I like probes that can accept screw-on alligator clips, very handy and safer.

Mark S.

- Joined

- Mar 3, 2013

- Messages

- 1,448

There are several YouTube videos on how to use a multimeter you might want to check out.

- Joined

- Aug 15, 2013

- Messages

- 2,110

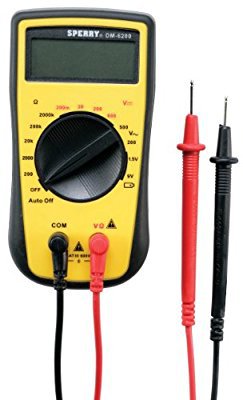

Here are a couple of links to Sperry online manuals that may be easier for you to read.

For current products:

http://www.sperryinstruments.com/en/resources/manuals

For discontinued products:

http://www.sperryinstruments.com/en/resources/legacy

Tom

For current products:

http://www.sperryinstruments.com/en/resources/manuals

For discontinued products:

http://www.sperryinstruments.com/en/resources/legacy

Tom

- Joined

- Nov 23, 2013

- Messages

- 593

A few things to keep in mind:

1. Check meter on a known source before you touch a "dead" wire. Make sure the meter will handle the expected voltage. I've seen some meters the max out at about 300 volts and it may not turn out well for you if you're reading 480 volts. Wear safety glasses when working on live equipment. Things happen and metal burns and is faster than you can blink.

2. Don't rotate dial while the leads are attached to a power source. Depending on the type/brand of meter you could rotate through the ohms or current setting and best case blow an internal fuse or blow the meter up.

3. Current is measured with the meter inline so it is basically a short circuit if you were to attach to a voltage source. See #2 for the results.

4. Test for power BEFORE you check resistance or continuity. Check both AC and DC if you're not sure what your source is. Once again see #2.

5. We like to think our machines are properly grounded but it may not be the case. If you can't get a reading to ground then check phase to phase to be sure you're getting an accurate reading.

1. Check meter on a known source before you touch a "dead" wire. Make sure the meter will handle the expected voltage. I've seen some meters the max out at about 300 volts and it may not turn out well for you if you're reading 480 volts. Wear safety glasses when working on live equipment. Things happen and metal burns and is faster than you can blink.

2. Don't rotate dial while the leads are attached to a power source. Depending on the type/brand of meter you could rotate through the ohms or current setting and best case blow an internal fuse or blow the meter up.

3. Current is measured with the meter inline so it is basically a short circuit if you were to attach to a voltage source. See #2 for the results.

4. Test for power BEFORE you check resistance or continuity. Check both AC and DC if you're not sure what your source is. Once again see #2.

5. We like to think our machines are properly grounded but it may not be the case. If you can't get a reading to ground then check phase to phase to be sure you're getting an accurate reading.

Reminder. ..

Always do this!

If measuring any type of current REMOVE THE LEADS FROM METER AND RECONFIGURE FOR VOLTS!

As mentioned above when measuring current or amps most non - clamping meters are in series and are same as a clip lead or wire.

Meters usually have a dedicated socket (s) for measuring amps ( some do not)

Many folks at all skill levels at one time or another will forget to move the lead from current (meter is a clip lead or short circuit) back to non - current configuration (high impedance or like open circuit) and go to measure a voltage resulting in blown fuse and damaged equipment before you see the spark.

Get in the habit of moving the wire as soon as finished.

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

Always do this!

If measuring any type of current REMOVE THE LEADS FROM METER AND RECONFIGURE FOR VOLTS!

As mentioned above when measuring current or amps most non - clamping meters are in series and are same as a clip lead or wire.

Meters usually have a dedicated socket (s) for measuring amps ( some do not)

Many folks at all skill levels at one time or another will forget to move the lead from current (meter is a clip lead or short circuit) back to non - current configuration (high impedance or like open circuit) and go to measure a voltage resulting in blown fuse and damaged equipment before you see the spark.

Get in the habit of moving the wire as soon as finished.

Sent from my SAMSUNG-SGH-I337Z using Tapatalk

Last edited by a moderator: