- Joined

- Mar 3, 2013

- Messages

- 1,448

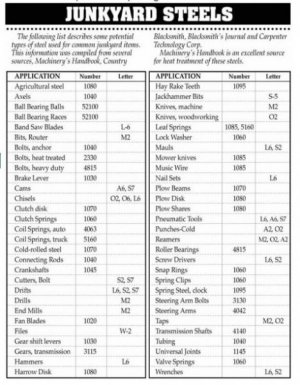

Q1) Someone had posted a list of common scrap steel items and what type of steel they typically were some months ago. I can't seem to find that list. Does anyone know where I can find that?

Q2) I have about 9 used lawnmower blades from a rear mounted tractor mower. Would these be weldable with MIG? I'm thinking about using them to make some new skid shoes for my tractor mounted snowblower.

Q2) I have about 9 used lawnmower blades from a rear mounted tractor mower. Would these be weldable with MIG? I'm thinking about using them to make some new skid shoes for my tractor mounted snowblower.