- Joined

- Jan 17, 2016

- Messages

- 71

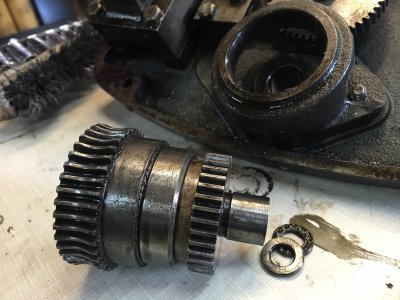

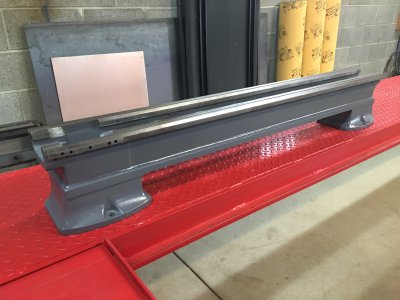

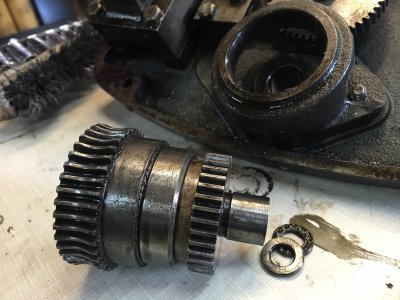

Hi...I just purchased a Logan 12" 2957V lathe and am beginning to clean and restore the lathe. I had been able to use the lathe a little before I started so I knew it need a lil TLC. It needed a rack pinion gear due to wear and there was a little too much backlash in the carriage. I started with the saddle/apron. After removing it and opening it up I discovered that some clutch parts (spring & ball thrust bearings), a brass (oiless) bearing, Crossfeed screw & nut, felts, saddle lock and some misc. woodruff keys and oilers would also be needed. I finished the apron (will be doing the saddle/cross slide/tool rest next.

Here are some pictures:

Here are some pictures: