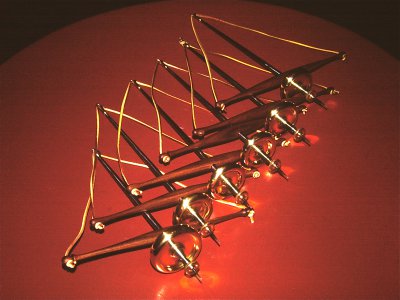

Hello! I recently bought an old dividing head, a "Yamatokoki" brand, "News" model. I read somewhere that it might be the company that became Yuasa. Appears to be a BS-0 clone. Anyway, there is no tailstock with it and only one of the dividing plates, the "B" plate. I'm trying to find the matching "A" and "C" plates but don't see any on the bay that are that diameter.

Anybody have any of those kicking around?

The center height of the dividing head is right about 4"--I suspect it is 3.937" because there is a Shars model tailstock that is that height. I do not have it set up to achieve that precise a measurement, however, so I can't say for sure. I would also be interested in a matching tailstock.

Any information on the dividing head would be appreciated, even if you don't have any spare parts for it.

Thanks,

Rick

Anybody have any of those kicking around?

The center height of the dividing head is right about 4"--I suspect it is 3.937" because there is a Shars model tailstock that is that height. I do not have it set up to achieve that precise a measurement, however, so I can't say for sure. I would also be interested in a matching tailstock.

Any information on the dividing head would be appreciated, even if you don't have any spare parts for it.

Thanks,

Rick