- Joined

- Apr 7, 2014

- Messages

- 343

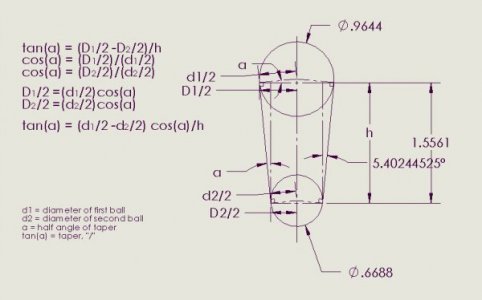

I was messing around with the idea of measuring a taper using two balls.

After I worked out the equation (which turned out to be pretty simple) and put it in a spreadsheet, I had to try it out.

I posted the attached video showing the measurement and spreadsheet.

The spreadsheet also has pages on measuring mouth openings of tapers. Joe Pi did a great video on measuring mouth openings with balls that got me thinking about measuring tapers using balls.

Here is Joe's video on measuring mouth openings using a gauge ball:

He is new to youtube, but has excellent machining tips.

I want to post the excel spreadsheet for free distribution.

Any ideas on the best way to do this? Update: link to EXCEL spreadsheet in post #5.

Thanks,

Chris

After I worked out the equation (which turned out to be pretty simple) and put it in a spreadsheet, I had to try it out.

I posted the attached video showing the measurement and spreadsheet.

The spreadsheet also has pages on measuring mouth openings of tapers. Joe Pi did a great video on measuring mouth openings with balls that got me thinking about measuring tapers using balls.

Here is Joe's video on measuring mouth openings using a gauge ball:

I want to post the excel spreadsheet for free distribution.

Any ideas on the best way to do this? Update: link to EXCEL spreadsheet in post #5.

Thanks,

Chris

Last edited: