- Joined

- Mar 26, 2014

- Messages

- 1,491

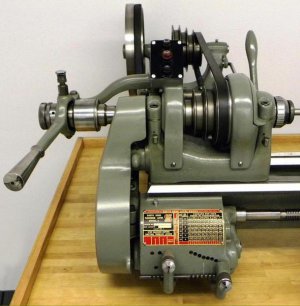

The metal tag on my Martin DLZ502 is basically unreadable. They couldn't have put it in a worse spot. 60 years of grime and tools laying on it.

Is the a way to kind of restore it so it's at least able to be read? I've tried cleaning it with degreaser. It helps a bit when you wipe oil or something wet.

Any ideas? Or does someone have the same lathe that you could take a photo and send to me?

Thanks

Martin

Sent from my iPad using Tapatalk

Is the a way to kind of restore it so it's at least able to be read? I've tried cleaning it with degreaser. It helps a bit when you wipe oil or something wet.

Any ideas? Or does someone have the same lathe that you could take a photo and send to me?

Thanks

Martin

Sent from my iPad using Tapatalk