- Joined

- Apr 21, 2015

- Messages

- 582

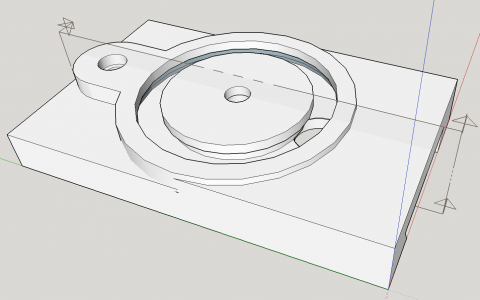

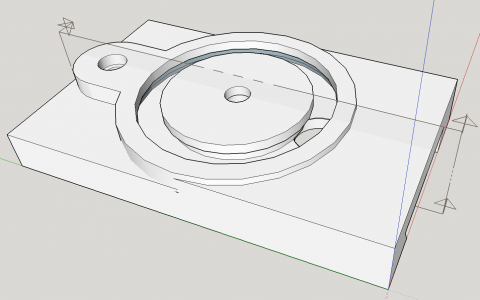

I'm attempting to replace (upgrade) the cross-feed slide on my old Logan lathe with the very nice iron casting I purchased from Andy Lofquist at Metal Lathe Accessories. I've been really wanting a "boring table" like George Thomas describes in his books and are apparently the norm with Myford lathes. The casting is really made for a South Bend lathe (see details at the practical machinist thread) which uses a different design for attaching the compound slide, but the overall dimensions still work quite nicely for my Logan (Wards) lathe. Here's a model I made of the original Logan slide:

I'm kinda stumped on how to mill the circular slot. I can't use a normal t-slot cutter because even the smallest won't fit into the opening (0.350"), and unlike a straight t-slot there is no opening to start the cut from the side. The slot itself is 0.540" from side to side and 0.200" in height.

I'm guessing I'll have to grind a special tool (sorta like a boring bar or maybe a gear cutter) but any advice would be greatly appreciated. I'm wondering if there is some sort of off-the-shelf cutting tool I'm unfamiliar with.

I have a (cheap import) rotary-table/dividing head. It's not the machining that has me stumped, it's what tool to use (and how to make one). I'm guessing it will be something like a cutter for making gears, only much smaller diameter.

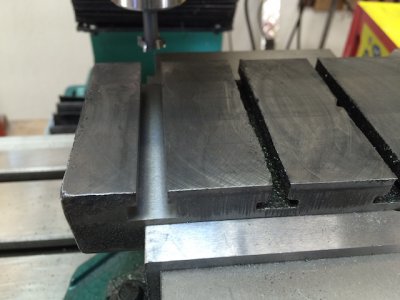

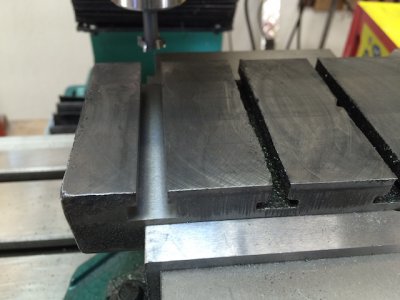

For now I'm just doing the rest of the basic squaring of the part, milling of the t-slots, and prep-work for cutting the dovetails. Eventually I have to get to the actual compound slot, though. Here's a pic of the straight t-slots that I milled today. That was straightforward. Machining cast iron is certainly messy (I've got all my ways covered with paper towels, and I also run the irritatingly noisy shop-vac continuously to catch most of the dust) but man is it a joy to work!

Any and all advice much appreciated.

Best regards,

--

Rex

P.S. I was surprised to find there doesn't appear to be a Logan forum on this site!

I'm kinda stumped on how to mill the circular slot. I can't use a normal t-slot cutter because even the smallest won't fit into the opening (0.350"), and unlike a straight t-slot there is no opening to start the cut from the side. The slot itself is 0.540" from side to side and 0.200" in height.

I'm guessing I'll have to grind a special tool (sorta like a boring bar or maybe a gear cutter) but any advice would be greatly appreciated. I'm wondering if there is some sort of off-the-shelf cutting tool I'm unfamiliar with.

I have a (cheap import) rotary-table/dividing head. It's not the machining that has me stumped, it's what tool to use (and how to make one). I'm guessing it will be something like a cutter for making gears, only much smaller diameter.

For now I'm just doing the rest of the basic squaring of the part, milling of the t-slots, and prep-work for cutting the dovetails. Eventually I have to get to the actual compound slot, though. Here's a pic of the straight t-slots that I milled today. That was straightforward. Machining cast iron is certainly messy (I've got all my ways covered with paper towels, and I also run the irritatingly noisy shop-vac continuously to catch most of the dust) but man is it a joy to work!

Any and all advice much appreciated.

Best regards,

--

Rex

P.S. I was surprised to find there doesn't appear to be a Logan forum on this site!