- Joined

- May 13, 2014

- Messages

- 5

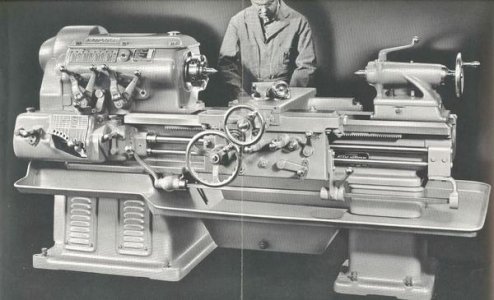

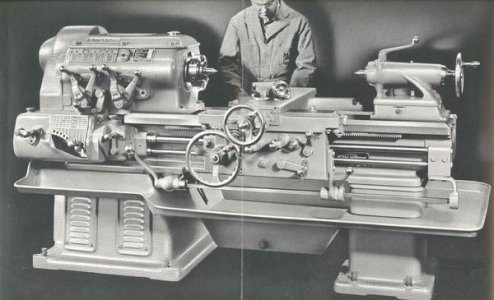

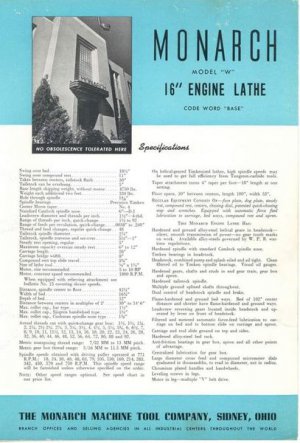

It was surely one of the happiest days for me when I bought my old Monarch lathe a few months ago. It was in a fairly good state, consider it was build more than 70 years ago. I can't say how she was treated through the years but I do know she found a good home with me

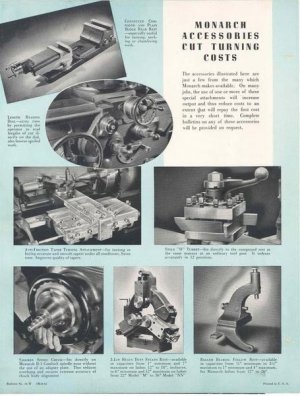

I have started to restore the machine but like many other restorations, anyway when it comes to me, lead to so many other little projects and things to make to assist or least make the restoration a bit better. My first side project was to build a sandblaster cabinet, wanted build one for so long but never come it, but this time I did. The sandblast cabinet is to blast most of the smaller parts clean before coating. The second side project is building an A-frame lifting beam.

I started off by taking off the QC gearbox and clean that up.

I have started to restore the machine but like many other restorations, anyway when it comes to me, lead to so many other little projects and things to make to assist or least make the restoration a bit better. My first side project was to build a sandblaster cabinet, wanted build one for so long but never come it, but this time I did. The sandblast cabinet is to blast most of the smaller parts clean before coating. The second side project is building an A-frame lifting beam.

I started off by taking off the QC gearbox and clean that up.