- Joined

- Nov 10, 2013

- Messages

- 837

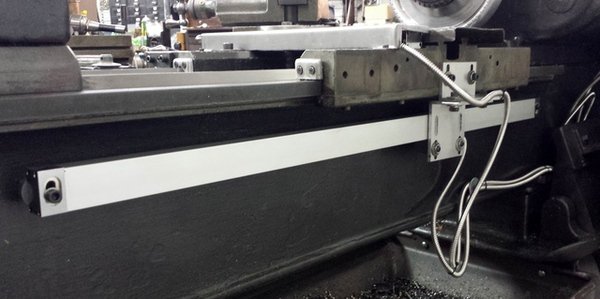

Finally decided to get a cheap 2 axis DRO for the Traytop. $220 shipped from Hong Kong with my choice of scale length.

Two things are surprising to me: First the price included shipping, how the heck do they ship so cheap from China? It costs $35 to ship a small USPS flat rate box to Finland. The Chinese government has to be financing all the free shipping. Second, The company literally dropped the packages off at DHL on the 19th and it arrived at my door (this morning) the 21st.

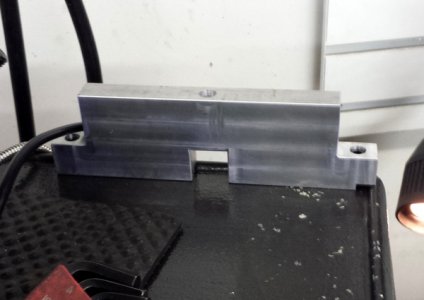

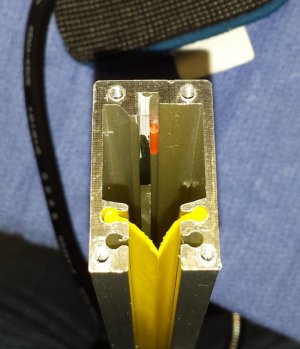

I ordered the scales a little long so I could adjust the lengths to fit on my machine. Better too long than too short! My cross slide was the primary concern. After checking out my very limited mounting options for the cross slide I cut the scale down to mount. I removed the end cap to get a view of how the glass was held in position. Some scales are glued in with silicone, this one had rubber spacers pushed into a channel and held in place with super glue.

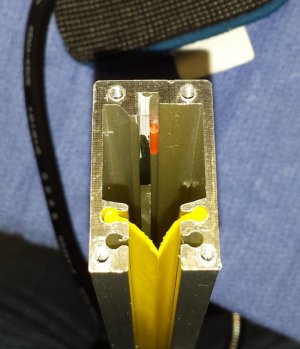

So I slid the reader head and removed the yellow guards by sliding them out of the housing being careful to not loose any springs or rollers that ride in the internal channel.

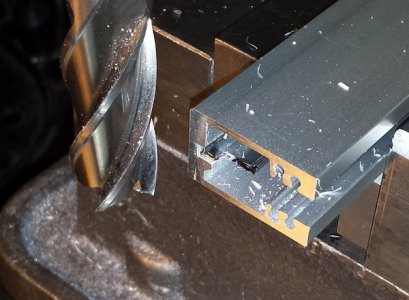

Then I band sawed around the casing as close to the glass as I could get then snapped the aluminum away from the scale.

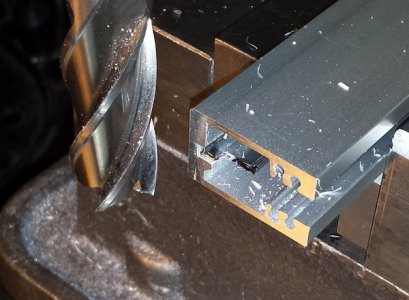

I snapped the scale off with a pair of pliers far enough inside the housing for the end cap to fit back on then set the scale up in the mill to square the housing back up for the end cap to fit back on.

Then I tapped the mounting holes in the end of the housing and put it all back together.

Two things are surprising to me: First the price included shipping, how the heck do they ship so cheap from China? It costs $35 to ship a small USPS flat rate box to Finland. The Chinese government has to be financing all the free shipping. Second, The company literally dropped the packages off at DHL on the 19th and it arrived at my door (this morning) the 21st.

I ordered the scales a little long so I could adjust the lengths to fit on my machine. Better too long than too short! My cross slide was the primary concern. After checking out my very limited mounting options for the cross slide I cut the scale down to mount. I removed the end cap to get a view of how the glass was held in position. Some scales are glued in with silicone, this one had rubber spacers pushed into a channel and held in place with super glue.

So I slid the reader head and removed the yellow guards by sliding them out of the housing being careful to not loose any springs or rollers that ride in the internal channel.

Then I band sawed around the casing as close to the glass as I could get then snapped the aluminum away from the scale.

I snapped the scale off with a pair of pliers far enough inside the housing for the end cap to fit back on then set the scale up in the mill to square the housing back up for the end cap to fit back on.

Then I tapped the mounting holes in the end of the housing and put it all back together.