@mickri Hey Chuck,

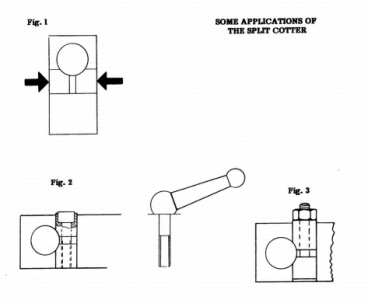

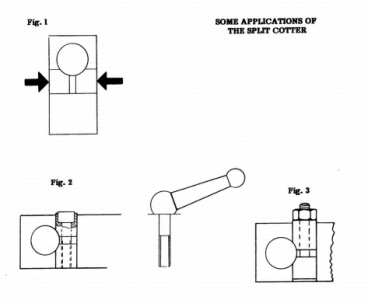

Is that the same mechanism that Guy Lautard calls the split cotter?

This picture is from his "The Machinist Bedside Reader 1", page 93.

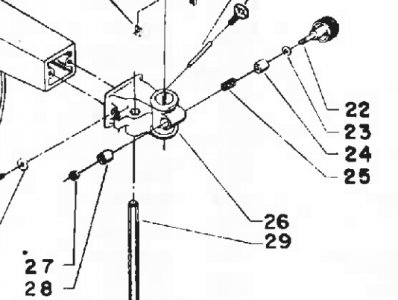

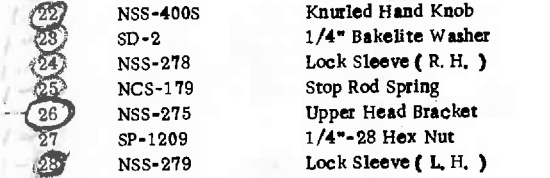

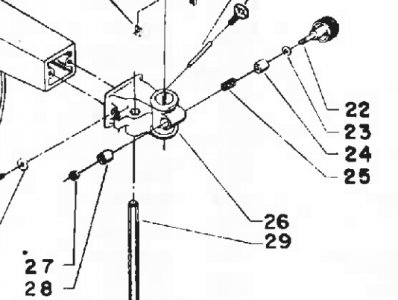

I have seen it used in my Delta/Rockwell model 40-440 scroll saw.

Actually my saw was missing a piece when I bought it.

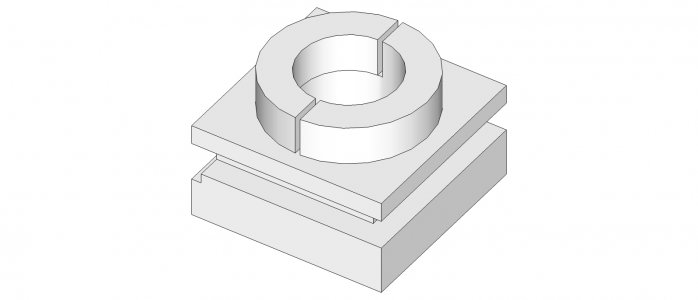

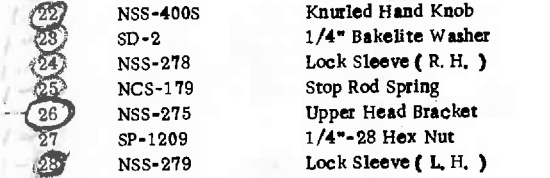

I made the brass half-clamp shown below (the nut sits in a hex recess in the brass).

That clamp holds the upper blade guide shown here:

Here's a manual for that:

http://vintagemachinery.org/pubs/detail.aspx?id=13980

Note they only call them left and right "Lock Sleeve".

If this is the same thing that you are thinking about, then I have been wondering the same thing!

Can you basically use a clamp that is half the above mechanism to securely hold a shaft that passes thru a block?

It would look like the above, but have my brass half as part of the original block.

Is that what you're thinking?

-brino

I made sure it would never close again .

I made sure it would never close again .