Firstly, apologies if this info is somewhere else, but i couldn't find it.

We have just bought a Bolton CQ9332A lathe and was looking to get a quick change tool post. Knowing very little about these, i ordered an AXA type set from Shars. This appeared to be too small!

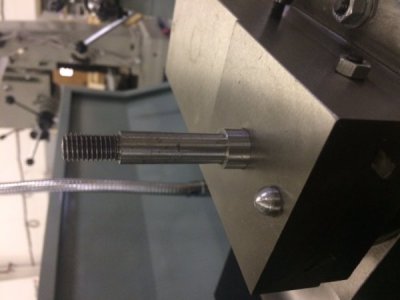

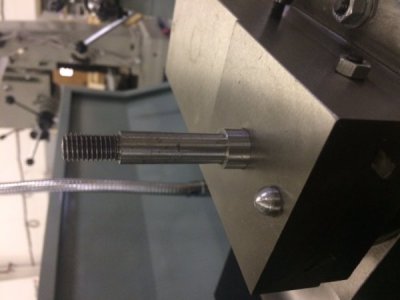

The Bolton lathe does not have a T-slot on the compound rest, instead it has a stud (14mm i think) with a thread on top and at the base is a small collar that is 16mm diameter (about 5/8" high).

If i get a BXA type post, what modification will i need. I saw something online where the guy made a sleeve to fit over the existing stud machined from the supplied QCTP stud. Is that the best way, or does someone have another path forward.

Thanks in advance

We have just bought a Bolton CQ9332A lathe and was looking to get a quick change tool post. Knowing very little about these, i ordered an AXA type set from Shars. This appeared to be too small!

The Bolton lathe does not have a T-slot on the compound rest, instead it has a stud (14mm i think) with a thread on top and at the base is a small collar that is 16mm diameter (about 5/8" high).

If i get a BXA type post, what modification will i need. I saw something online where the guy made a sleeve to fit over the existing stud machined from the supplied QCTP stud. Is that the best way, or does someone have another path forward.

Thanks in advance