4

4GSR

Forum Guest

Register Today

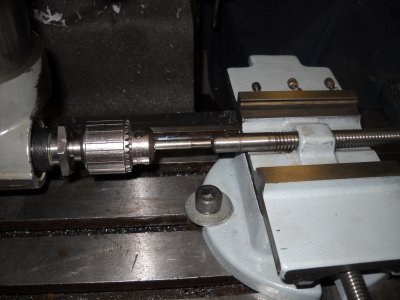

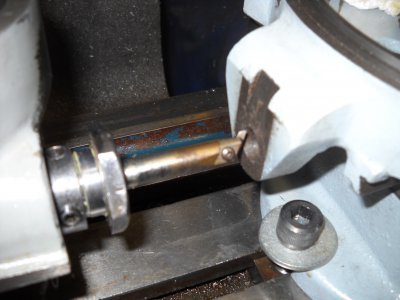

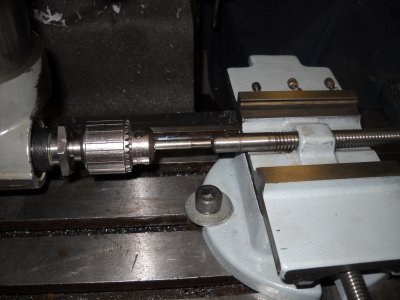

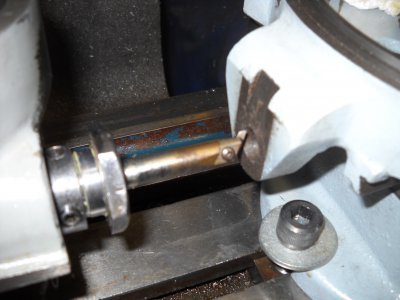

I bought this 8" Palmgren rotary table at an estate sale a while back. It was very cruded up from many years of neglect and Mother Nature, the elements attacking it.

The rotary table was completely disassembled, cleaned, and painted before re-assembling. I had to rework all of the dovetail slides to get them running reasonable straight again. I also re-ground the top and the bottom to make it look nice.

Pictures attached are showing the "before, work done, and the finished RT".

Enjoy!

The rotary table was completely disassembled, cleaned, and painted before re-assembling. I had to rework all of the dovetail slides to get them running reasonable straight again. I also re-ground the top and the bottom to make it look nice.

Pictures attached are showing the "before, work done, and the finished RT".

Enjoy!