Hey guys-

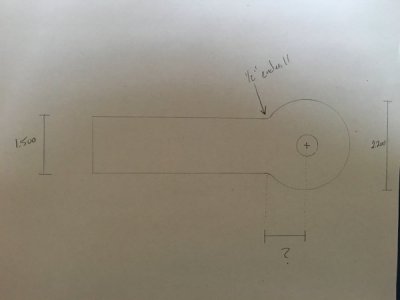

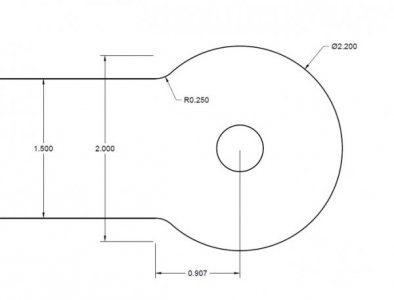

I suspect I'm missing something pretty simple, but can't for the life of me sort it out. Here's the situation: the 1.5" measurement is machined, but none of the 2.2" diameter is. I need to poke a hole in the center of the 2.2" that I can use to center the part on the rotary table under the spindle. The hope is to very carefully blend the 2.2" diameter with the small radius left by the 1/2" endmill with a nice finish on both sides. Using the right triangle formula (adding .250 per side to account for the 1/2" tool) I'm coming up with 1.814 (rounded) of which I need to take 1/2 to get to the center... so .907. So far so good right? The problem is when I actually do the machining, it becomes apparent that the .907 number is visibly too small... by probably 50 thou or so. If I hit the 2.2" measurement perfectly, there's still quite a ways to go before the curves are blended. If I keep going until they're blended nicely, my diameter goes down to about 2.1". Like I said, I know I'm missing something obvious, but figured I'd ask for help before I waste any more time/ material. Thanks in advance!

I suspect I'm missing something pretty simple, but can't for the life of me sort it out. Here's the situation: the 1.5" measurement is machined, but none of the 2.2" diameter is. I need to poke a hole in the center of the 2.2" that I can use to center the part on the rotary table under the spindle. The hope is to very carefully blend the 2.2" diameter with the small radius left by the 1/2" endmill with a nice finish on both sides. Using the right triangle formula (adding .250 per side to account for the 1/2" tool) I'm coming up with 1.814 (rounded) of which I need to take 1/2 to get to the center... so .907. So far so good right? The problem is when I actually do the machining, it becomes apparent that the .907 number is visibly too small... by probably 50 thou or so. If I hit the 2.2" measurement perfectly, there's still quite a ways to go before the curves are blended. If I keep going until they're blended nicely, my diameter goes down to about 2.1". Like I said, I know I'm missing something obvious, but figured I'd ask for help before I waste any more time/ material. Thanks in advance!