- Joined

- Apr 30, 2012

- Messages

- 2,401

This may be a little early to start this because i'm waiting for all the parts but here is what i have so far

I thought this was going to be pretty easy but what I'm finding out is there are really a lot of different versions of this mill with all different z axis column lift configurations so I'm not going to have the luxury of using someone elses plans. Oh well just adds to the fun

I have the mill and I took it apart after a 2 hour check out run, I have never used it it's new.

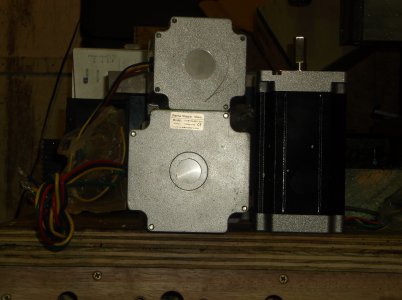

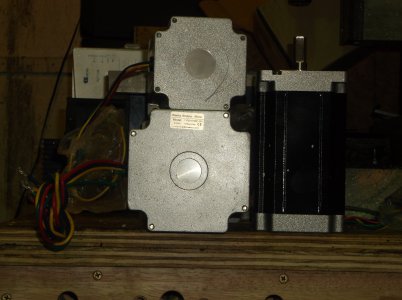

I have my motors for the 4 axis and power supplies they are 4200 oz/in for z, 1600 oz/in for x and y, and an 800 oz/in for a rotary index. the power supplies (3)will be running 60 volt and the 4200's controller has it's own power supply.

I'm still waiting for the ball screws, bearings, couplers and a 5 axis breakout board with relay.

once I get the mechanical parts I can start on the motor mounts. these will be direct drive and that is why the motors are so big. the gear head on the mill weighs 300lbs and I wanted to use this mass to keep down vibration so I'm not going to use lift cylinders on the head.

here are some pics of what I have so far and i will give my list of parts and cost when I get it all together

I figure starting this now will help remind me to take pictures but I also going to be slow because of my health I cant lift anything or stand for very long, so I'll be waiting for my son and son-in-laws help for a lot of this

steve

I thought this was going to be pretty easy but what I'm finding out is there are really a lot of different versions of this mill with all different z axis column lift configurations so I'm not going to have the luxury of using someone elses plans. Oh well just adds to the fun

I have the mill and I took it apart after a 2 hour check out run, I have never used it it's new.

I have my motors for the 4 axis and power supplies they are 4200 oz/in for z, 1600 oz/in for x and y, and an 800 oz/in for a rotary index. the power supplies (3)will be running 60 volt and the 4200's controller has it's own power supply.

I'm still waiting for the ball screws, bearings, couplers and a 5 axis breakout board with relay.

once I get the mechanical parts I can start on the motor mounts. these will be direct drive and that is why the motors are so big. the gear head on the mill weighs 300lbs and I wanted to use this mass to keep down vibration so I'm not going to use lift cylinders on the head.

here are some pics of what I have so far and i will give my list of parts and cost when I get it all together

I figure starting this now will help remind me to take pictures but I also going to be slow because of my health I cant lift anything or stand for very long, so I'll be waiting for my son and son-in-laws help for a lot of this

steve