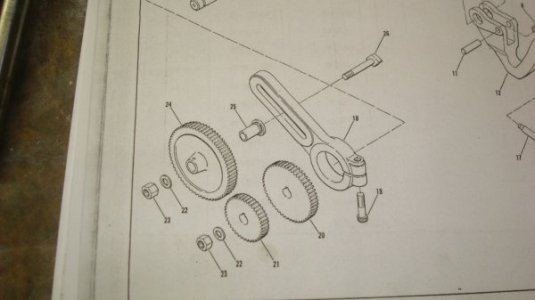

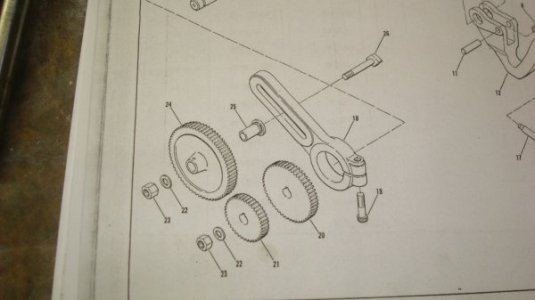

Guys on my SB Fourteen project I was on a good roll,everything was going smooth until today.I am posting my problem separate from my restoration project cause I just want it to be a good clean post.My problem is the bushing that is for the gear that pivots that drives the QCGB.The bore of the gear is .757 and the bushing OD is .744 and its alittle rough kinda like no oil was ever added.Bushing is part#25 and the gear is #24.Anyway I think I have couple choices:1)Is to try and make another bushing or 2)Bore the gear alittle bigger and turn the OD of the bushing down alittle so that maybe I can get one of those oil embedded sleeves and press it in.Guys it seems to me that SB should have design these parts to have a sleeve so that over time it could be replace but I'm sure there's a reason why they did not.Anyway guys I don't have much experience with these type of issues,I don't know what the gear is made of nor do I know what the bushing is made of.If its mild steel then maybe I stand a chance.I really would like to go with the oil embedded sleeve cause its alittle more forgiving than steel against steel.If you have any ideals or suggestions please let me know,cause I do know that SB parts are out of price range.Thanks kroll