Did about another hour of scraping on the bottom and I am getting pretty comfortable getting a good bluing. The hinging method helped my identify when I was getting convexity in the middle and I could preferentially scrape to resolve this issue.

In the image below, I am trying to scrape only the areas needed to resolve the side to side taper and the convexity of the bottom.

I worked at this for a while but just could not get consistent measurements on the parallelism of the bed to the bottom. I figured the bed must also be twisted, so I disassembled and cleaned the vise to prepare for scraping.

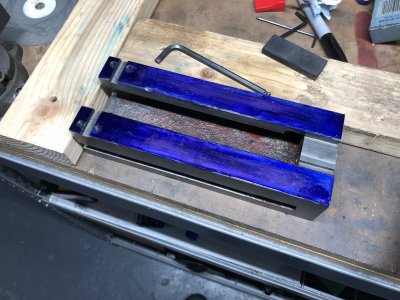

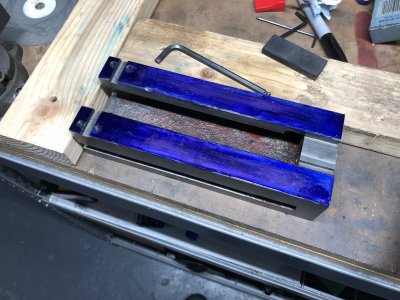

Here is an initial blue up. Somewhat as expected as there was a lot of raised material around the tapped holes. I wonder if they were drilled and tapped after grinding? Anyways, I figured at this point that the blue on the left side of the picture was just a false reading due to the part being lifted at the threaded holes, but later on I realized that the left edge was significantly raised up in comparison to the rest of the bed.

Since it is hard to get a good bluing on surface ground finishes, I used layout fluid to paint the top surface. I then executed two scraping passes to texture the surface, looking for even scrape patterning and spacing (thus scraping "straight down")

Here is what that looked like.

I spent another hour trying to develop this surface down to flat. Here is a summary of what I have discovered in the part geometry.

Bottom not flat: bottom was concave (banana shaped) by roughly 0.003"

Bottom not parallel to bed: after developing the bottom to be flat, a widthwise taper of ~0.0006" and a lengthwise taper of ~0.0002" were present.

Bed not flat: bed is concave by roughly 0.003"

Bed rails not flat: each rail has a concavity along the length (like a half pipe) of roughly 0.0008"

I made a lot of progress towards getting this flat. Probably would be done by now if I didn't make mistakes - more on that later. I would guess one more hour to get it flat, one hour to high point to decent bearing, and one hour to get the bottom parallel to the top.

Each cycle looks like this:

1) Examine bluing (use sharpie to mark exclusion zones if needed)

2) Scrape bluing

3) Dust off chips

4) Wipe clean with alcohol

5) Stone lightly with a fine india stone

6) wipe clean with alcohol

7) Clean off dust with light compressed air

8) Use brayer to smooth out the blue on the plate

9) Print part with blue

During the latter part of roughing in the bed I got impatient and thought to try a bench stone to hit off the high spots. I only gave it maybe a dozen swipes, but I did a lot of damage in that short action. If you can see in the image below, the outside edges of the bed rails got rolled off very quickly (they were even high before stoning). This is going to require several scraping passes to drop the surface down to the level of the edges that got stoned. Probably cost me at least an hour of work in only 15 seconds - ugh. I called it a night here.

What I learned on day 2 of scraping:

1) It is very easy to get dirt, dust, and grit in your blue on the plate. When you do, you typically have to remove a ton of blue and start over. I had to develop and good strategy of cleaning the part before bluing it. The scraping chips fall into the vise body during scraping and then fall onto the plate when it is inverted. The extra cleaning time is much better than constantly needing to wipe off the blue and start over.

2) A rubber brayer does a good job of picking up a bit of dust and grit from the blue on the surface plate. The dust sticks better to the rubber roller than the plate. Keeping the brayer clean and rolling it over the blue at least every few cycles helps keep the plate clean.

3) Bench stones have no place in scraping. A fine

india hard arkansas stone or a precision ground flat stone (PFG) is the only option for deburring.

4) You need to rough scrape longer than you think. I keep switching to going after high points long before the surface is flat or geometrically correct.

5) Hinging is really important for determining surface flatness.

6) Carbide hand scrapers require more frequent sharpening than expected. I notice the edge does not cut as easily after 4-5 cycles. 2-3 swipes on 1500 grit diamond gets it back to sharp. I can visually see if the blade is dull by if there is any light reflected from the corner of the blade. Even the faintest sliver indicates dullness.

7) Scraping near edges and holes is very tricky. It is hard to get yourself to cut deep enough just inside from the edge, but not roll over the edge.

I do think that a few more hours will get this

much better than what I started with. On my next scraping attempt, I expect to be 25% more efficient if I can avoid the same mistakes I've done here.