- Joined

- Oct 4, 2016

- Messages

- 9

My Shars 9x12x3 "Grade A" surface plate arrived today. "Accuracy" good to .0001", according to the specs. I was hoping to use this as a general surface for measurements, and I'm toying with the idea of using it to scrape-in some of the smaller surfaces on my import mini-lathe (it's not like I could really make it any worse...).

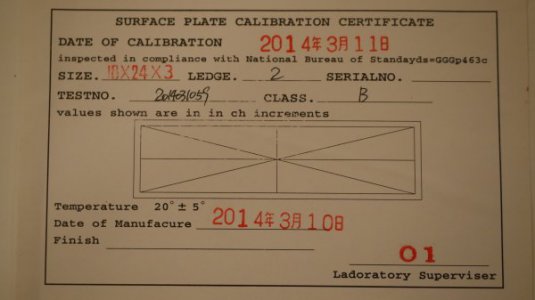

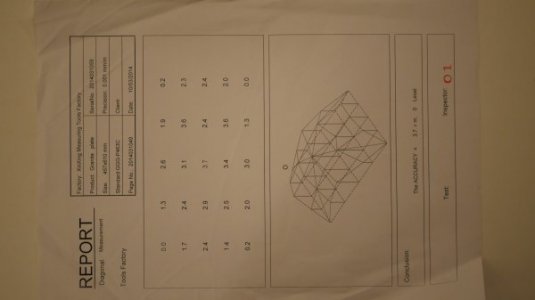

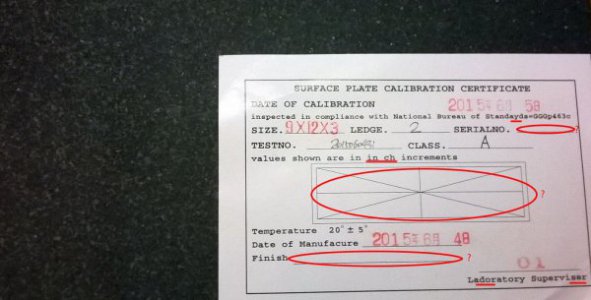

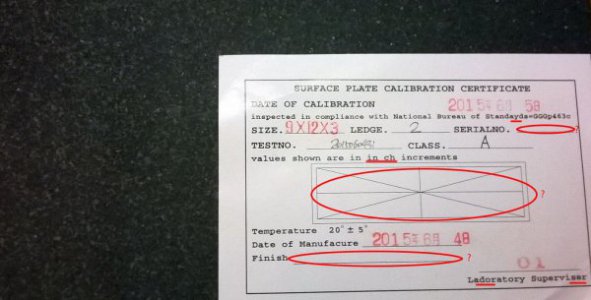

Now, I've heard good things about Shars stuff in general, but I couldn't find much specific to these ultra-budget surface plates (this was under $30 before shipping) - and this "calibration certificate" reeeeeeaaaallllyyy doesn't inspire much confidence.

Horrific typos aside, there is no indication on here whatsoever that anything was measured. Most fields that would indicate such are blank.

Now, seeing as I bought a $27 surface plate to do some *relatively* accurate measurements in the first place, I obviously have no way of interrogating this surface for flatness.

Thoughts? Experiences? Opinions? I'd love to hear 'em.

Now, I've heard good things about Shars stuff in general, but I couldn't find much specific to these ultra-budget surface plates (this was under $30 before shipping) - and this "calibration certificate" reeeeeeaaaallllyyy doesn't inspire much confidence.

Horrific typos aside, there is no indication on here whatsoever that anything was measured. Most fields that would indicate such are blank.

Now, seeing as I bought a $27 surface plate to do some *relatively* accurate measurements in the first place, I obviously have no way of interrogating this surface for flatness.

Thoughts? Experiences? Opinions? I'd love to hear 'em.