- Joined

- Nov 25, 2015

- Messages

- 8,279

So I am unable to do any work in the shop until the MRI now that I had my eyes xrayed.

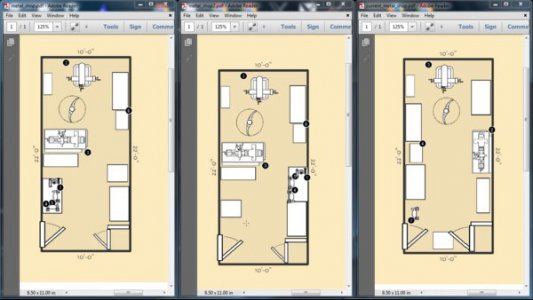

So earlier in the week I used Grizzly's shop tool to figure out how to rearrange my shop to get more space out of it.

I want to separate the grinders from everything. And maybe add a new tool.

So I came up with the current shop (far right), and 2 versions of a new layout.

I really like the lathe in the new position, but nothing is fitting the way I hoped.

I have shelves hanging on the walls to hold more stuff. And they were inteferring with my boxes. So I had to raise them. Not what I wanted, and one of the reasons I wanted to move my lathe as I wanted to raise it. I did about 2 inches, and now if feels way nicer. Now if everything else would work... None of it is.

All this work and not sure what I am going to do next..

So earlier in the week I used Grizzly's shop tool to figure out how to rearrange my shop to get more space out of it.

I want to separate the grinders from everything. And maybe add a new tool.

So I came up with the current shop (far right), and 2 versions of a new layout.

I really like the lathe in the new position, but nothing is fitting the way I hoped.

I have shelves hanging on the walls to hold more stuff. And they were inteferring with my boxes. So I had to raise them. Not what I wanted, and one of the reasons I wanted to move my lathe as I wanted to raise it. I did about 2 inches, and now if feels way nicer. Now if everything else would work... None of it is.

All this work and not sure what I am going to do next..

That's a man so that I have scale about what it would be to be in that alcove.

That's a man so that I have scale about what it would be to be in that alcove.