- Joined

- Feb 2, 2014

- Messages

- 1,059

I started this project about a week ago after getting some inspiration from posts like "A dividing head by Wayne" , and from Mark Frazier's builds and several others here on the forum.

I have been experimenting making spur gears and gear reduction units but the post I did about a year ago on worm gears still had me thinking. You can really get a lot of reduction in a small space with a worm gear.

This is the new worm I made to see how it would turn out.

It has 90 teeth using a 1/2" by 13 tap.

It turned out very well with nicely formed teeth. It is mounted in a 1.5 by 3.5 block of 6061 about 18" long. When you design as you go along I have learned not to cut the parts to size but leave them longer than you think you will need them. This usually turns out to be the case.

This is how I bored the block for the bearings with a medium press fit. I didn't press them all the way in as I didn't know just where I wanted the worm gear located until later.

I turned the ends down to make bearing surface and then pressed the 0.750 bar through the center of the block. I also bored the worm axle out for a #3 Morse taper.

I cut the block back to length plus about 1/2 inch more for future needs.

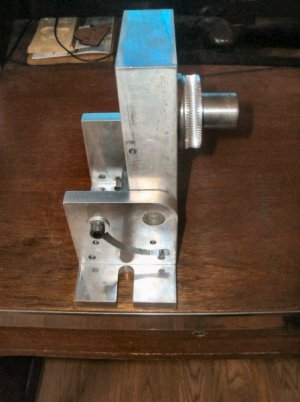

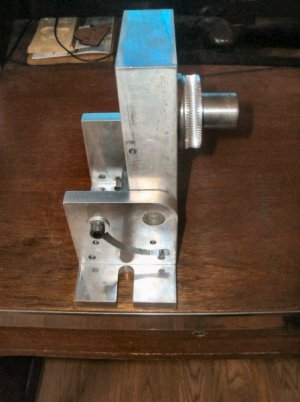

I had a 4th axis that I made years back and it has been replaced with better version so I just used some of that material for this project. Please disregard the extra holes.

The tilt works well and the base fits my table slots so I will keep on building. Who knows just what it will look like.

Thanks for looking.

Ray

I have been experimenting making spur gears and gear reduction units but the post I did about a year ago on worm gears still had me thinking. You can really get a lot of reduction in a small space with a worm gear.

This is the new worm I made to see how it would turn out.

It has 90 teeth using a 1/2" by 13 tap.

It turned out very well with nicely formed teeth. It is mounted in a 1.5 by 3.5 block of 6061 about 18" long. When you design as you go along I have learned not to cut the parts to size but leave them longer than you think you will need them. This usually turns out to be the case.

This is how I bored the block for the bearings with a medium press fit. I didn't press them all the way in as I didn't know just where I wanted the worm gear located until later.

I turned the ends down to make bearing surface and then pressed the 0.750 bar through the center of the block. I also bored the worm axle out for a #3 Morse taper.

I cut the block back to length plus about 1/2 inch more for future needs.

I had a 4th axis that I made years back and it has been replaced with better version so I just used some of that material for this project. Please disregard the extra holes.

The tilt works well and the base fits my table slots so I will keep on building. Who knows just what it will look like.

Thanks for looking.

Ray