- Joined

- Nov 2, 2012

- Messages

- 415

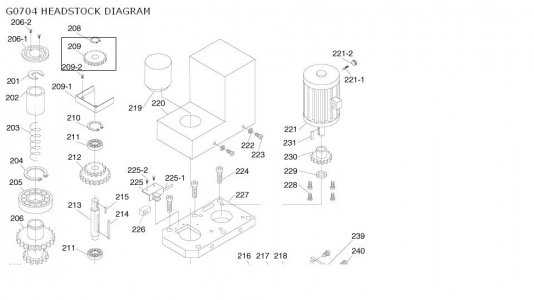

Anyone know of a supplier not named Grizzly that might have a 37t gear for my mill? (Part #209 in the drawing.) I made a mistake, crashed the cutter and the gear sheared some teeth. Sacrificial, for sure.

I don't mind paying the $10 for my mistake, but they have been back-ordered since at least mid-Feb, and I just got a card saying no known stock date is in sight. I suppose it's strange, but I'd like to use this thing at least occasionally. Anybody selling clones I can check with?

Thanks,

Ryan

I don't mind paying the $10 for my mistake, but they have been back-ordered since at least mid-Feb, and I just got a card saying no known stock date is in sight. I suppose it's strange, but I'd like to use this thing at least occasionally. Anybody selling clones I can check with?

Thanks,

Ryan