- Joined

- Feb 1, 2015

- Messages

- 9,575

I use a spring loaded tap guide whenever I tap holes on the mill. It has some problems though. Frequently, I don't have enough head room to fit a tap, a tap wrench, and the tap guide. I am also limited to 1/4" taps and smaller. Finally, the usable travel is about .4" which is frequently not sufficient to fully tap a hole.

I had started to design my own tap wrench which could accommodate taps up to 5/8" and would have a short profile. Making a self centering tap wrench could be accomplished but with some difficulty.

Last week, I was in our local DIY and stopped by the taps to see if I could get some ideas. There I found a tap wrench made by Irwin ( P/N 1766069) which seemed to fit the bill. At 2-1/2", it was considerably shorter than a traditional collet type tap wrench. It was speced at accommodating taps from 1/4" to 1/2". There was a socket for a 3/8" drive which could be used for a tap guide, and it had a 1" hex for driving with a wrench if you really needed some torque. At a little over $14 with store rebates, I picked one up.

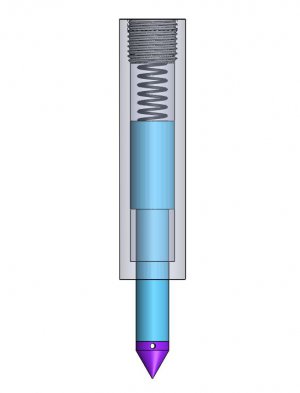

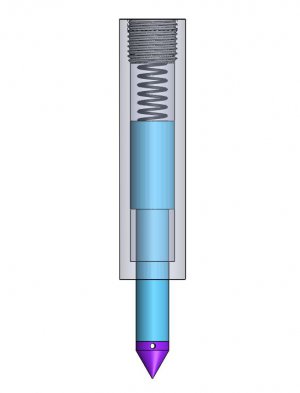

Once home, I checked it out. It actually will accommodate taps from #12 through 9/16". The 3/8" socket will seat a .380" pin. I set about designing the tap guide, basically an upsized version of the commercial guide. The housing is 3/4" in diameter to fit my 3./4" R8 collet. I designed the travel to be 1.3". I also added a replaceable tip so I could easily go from a point to a countersunk end. The countersunk end also serves as the centering pin for the Irwin tap wrench. The Irwin wrench is unmodified.

The project was almost entirely lathe work. The only exception was milling a screwdriver slot in the threaded retaining plug. For the housing, the plunger, and the two tips, I used some bar stock salvaged from old printers. It is a free machining steel with characteristics similar to 41L40. The 9/16" - 18 threaded plug was cut from a length of threaded rod. On modification made on the fly was to add a boss to center the spring. A 1/8" screwdriver slot was milled.

The assembled tap guide and tap wrench extends about 2.6" below the R8 collet. The actual travel is 1.5" which will handle most tapping needs. The violet part is the replaceable tip it has a 1/4-28 male thread to mate with the threaded socket in the blue plunger. The spring extends downward into a socket in the plunger. The photo shows the commercial tap guide in the lower left, the new guide, the tip for engaging the Irwin tap wrench, and the Irwin tap wrench in the upper right.

I had started to design my own tap wrench which could accommodate taps up to 5/8" and would have a short profile. Making a self centering tap wrench could be accomplished but with some difficulty.

Last week, I was in our local DIY and stopped by the taps to see if I could get some ideas. There I found a tap wrench made by Irwin ( P/N 1766069) which seemed to fit the bill. At 2-1/2", it was considerably shorter than a traditional collet type tap wrench. It was speced at accommodating taps from 1/4" to 1/2". There was a socket for a 3/8" drive which could be used for a tap guide, and it had a 1" hex for driving with a wrench if you really needed some torque. At a little over $14 with store rebates, I picked one up.

Once home, I checked it out. It actually will accommodate taps from #12 through 9/16". The 3/8" socket will seat a .380" pin. I set about designing the tap guide, basically an upsized version of the commercial guide. The housing is 3/4" in diameter to fit my 3./4" R8 collet. I designed the travel to be 1.3". I also added a replaceable tip so I could easily go from a point to a countersunk end. The countersunk end also serves as the centering pin for the Irwin tap wrench. The Irwin wrench is unmodified.

The project was almost entirely lathe work. The only exception was milling a screwdriver slot in the threaded retaining plug. For the housing, the plunger, and the two tips, I used some bar stock salvaged from old printers. It is a free machining steel with characteristics similar to 41L40. The 9/16" - 18 threaded plug was cut from a length of threaded rod. On modification made on the fly was to add a boss to center the spring. A 1/8" screwdriver slot was milled.

The assembled tap guide and tap wrench extends about 2.6" below the R8 collet. The actual travel is 1.5" which will handle most tapping needs. The violet part is the replaceable tip it has a 1/4-28 male thread to mate with the threaded socket in the blue plunger. The spring extends downward into a socket in the plunger. The photo shows the commercial tap guide in the lower left, the new guide, the tip for engaging the Irwin tap wrench, and the Irwin tap wrench in the upper right.