- Joined

- Dec 3, 2013

- Messages

- 1,844

I recently ordered a large-ish piece of aluminum from one of the web vendors for a paying job. I could have sourced it locally but the supply house I can get this size for a reasonable cost is 40 miles away and for the shipping cost it was worth ordering plus I had some lead time.

The published policy for cutting is the ordered length is guaranteed -0.000" +0.125".

I ordered a 1.5" long piece of 8" aluminum round. Typically 30 to 40 thou will be lost in cleanup so if it came at the 1.5 minimum all would be good.

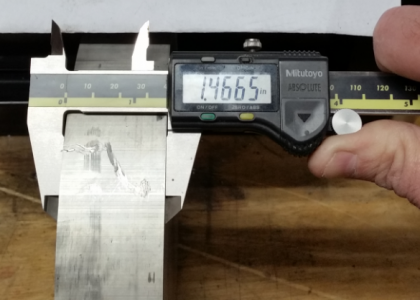

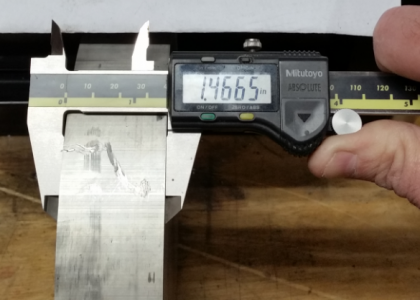

Piece #1

Okay I can understand someone making a mistake. It can happen. It's kind of obvious but I will give them the benefit of the doubt.

I sent an email with photos to customer service and they promptly sent out a new piece. I still have some time so if they get it to me by Friday like they say all should be good.

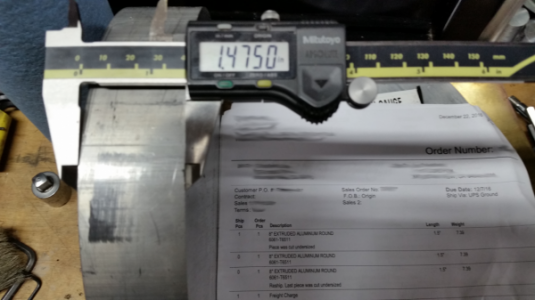

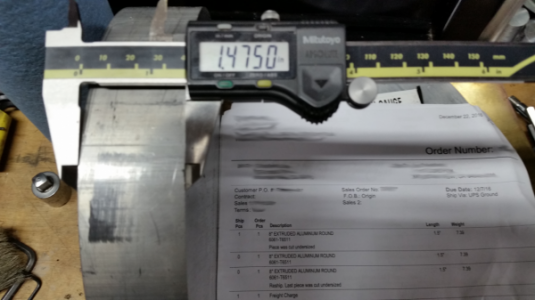

Piece #2

Really? Some basic training on measuring is in order. You would think that when they got the re-cut order because the first was short they would error on the larger side. Too late in the day to get locally now I'm going to miss my deadline, not cool.

Another email to CS with photos but this time I started getting excuses about cutting short pieces and the saw wanders a little and blah blah blah. Like I could tell my customers something like that.

A polite but strongly worded reply back to CS reminding them of their guarantee and something to the effect that this isn't rocket science, this time CCing the sales department as well, resulted in an apology and a reassurance that the warehouse manager would personally QC the item so the correctly cut material would be sent out overnight (meaning by Monday).

Piece #3

Speechless. There are no words for this level of incompetence.

I informed CS of the latest failure and told them I would source the material locally, which I did and had the material within a few hours and the part completed by the next morning one day late.

Their response was a full refund. At least they got that right!

Some would say I should have just ordered it a little longer to begin with but I have never had this problem before with any of the local supply houses. I'd rather spend money on tools than lining my chip pan.

The published policy for cutting is the ordered length is guaranteed -0.000" +0.125".

I ordered a 1.5" long piece of 8" aluminum round. Typically 30 to 40 thou will be lost in cleanup so if it came at the 1.5 minimum all would be good.

Piece #1

Okay I can understand someone making a mistake. It can happen. It's kind of obvious but I will give them the benefit of the doubt.

I sent an email with photos to customer service and they promptly sent out a new piece. I still have some time so if they get it to me by Friday like they say all should be good.

Piece #2

Really? Some basic training on measuring is in order. You would think that when they got the re-cut order because the first was short they would error on the larger side. Too late in the day to get locally now I'm going to miss my deadline, not cool.

Another email to CS with photos but this time I started getting excuses about cutting short pieces and the saw wanders a little and blah blah blah. Like I could tell my customers something like that.

A polite but strongly worded reply back to CS reminding them of their guarantee and something to the effect that this isn't rocket science, this time CCing the sales department as well, resulted in an apology and a reassurance that the warehouse manager would personally QC the item so the correctly cut material would be sent out overnight (meaning by Monday).

Piece #3

Speechless. There are no words for this level of incompetence.

I informed CS of the latest failure and told them I would source the material locally, which I did and had the material within a few hours and the part completed by the next morning one day late.

Their response was a full refund. At least they got that right!

Some would say I should have just ordered it a little longer to begin with but I have never had this problem before with any of the local supply houses. I'd rather spend money on tools than lining my chip pan.