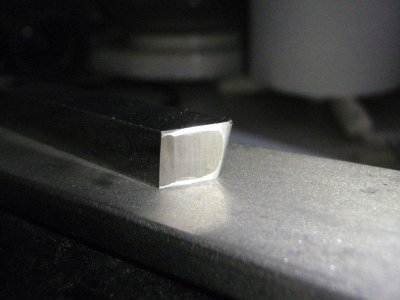

Here are some pictures of my first attempt at tool grinding. I'm pretty new to machining and I have never ground a tool before today. I don't have anyone to ask on how well I did or on what mistakes I made and/or corrections to make so I thought I would ask you all? I tried to follow these four steps

My first attempt was to create a rounded tip tool...see pics. My second attempt was to create a sharp pointed tip and my third attempt was to make a cut off tool. All tools were created using HSS bits. I tried all three tools on some 1 inch round aluminium. They all cut pretty well, nice smooth finish with the round tip and good facing with the sharp point. My only problem came with the cut off tool. It seemed to work ok, but it would leave a very small raised section on the inside top piece that was cut off, also it would leave a slight hump on the inside of the cut off piece. Let me know what you think. Thanks

Patrick

- Grind the end relief

- Grind the left side relief

- Grind the tip rake

- Round the tip

My first attempt was to create a rounded tip tool...see pics. My second attempt was to create a sharp pointed tip and my third attempt was to make a cut off tool. All tools were created using HSS bits. I tried all three tools on some 1 inch round aluminium. They all cut pretty well, nice smooth finish with the round tip and good facing with the sharp point. My only problem came with the cut off tool. It seemed to work ok, but it would leave a very small raised section on the inside top piece that was cut off, also it would leave a slight hump on the inside of the cut off piece. Let me know what you think. Thanks

Patrick