- Joined

- Oct 31, 2016

- Messages

- 2,643

Welcome to the forum. We love to help people spend their money on tooling.

Since you are a machinist student why don't you make a Norman style QCTP. Fraction of the cost and you will gain lots of experience making the post and the holders. Lots of members on here have made them. Not hard to make. That's what I did. They can be made without a mill. All you need is a lathe and a drill.

www.hobby-machinist.com

www.hobby-machinist.com

Since you are a machinist student why don't you make a Norman style QCTP. Fraction of the cost and you will gain lots of experience making the post and the holders. Lots of members on here have made them. Not hard to make. That's what I did. They can be made without a mill. All you need is a lathe and a drill.

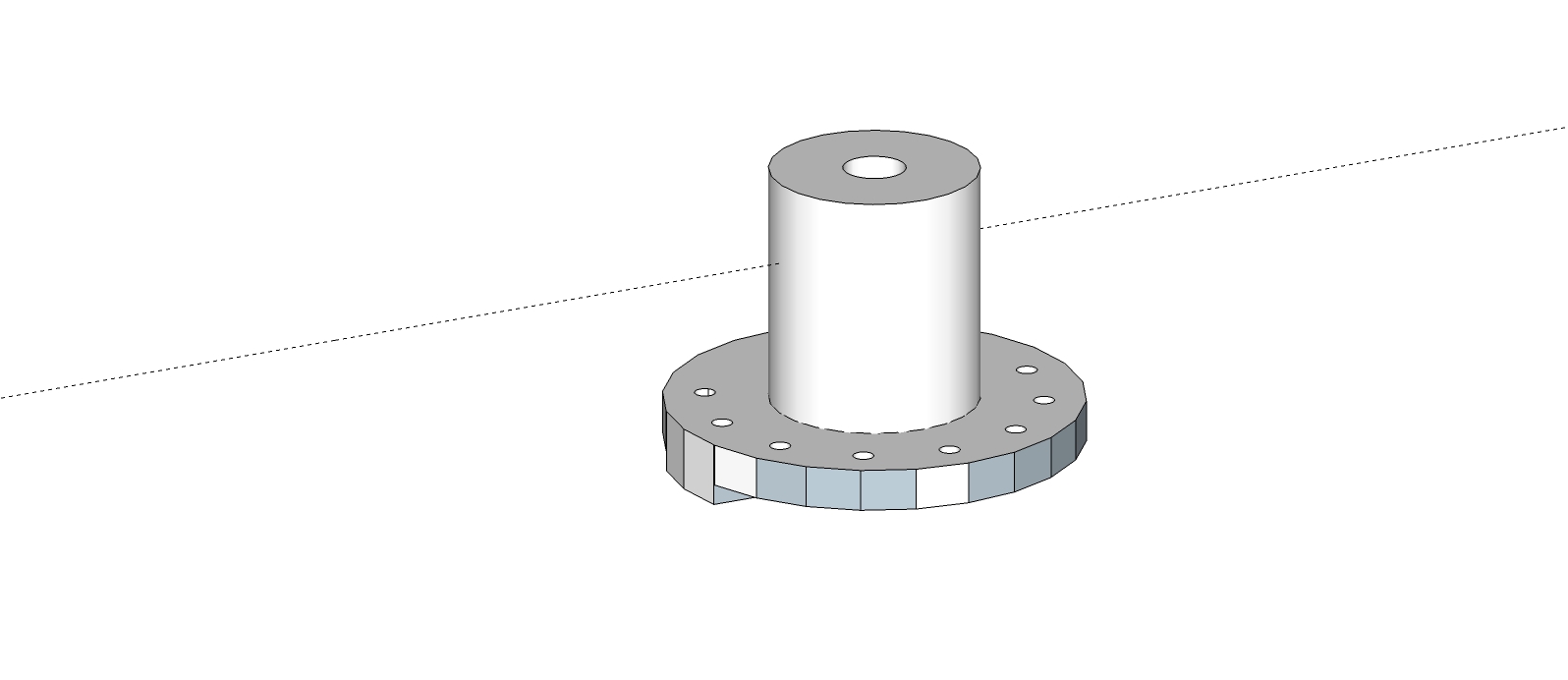

Norman Style QCTP

I have been using my Norman style QCTP and have sorted out the problems that came up through use. Instead of placing my findings at the end of the very long thread on making it I thought that it would be better to put everything in one place. First off you have to measure the distance from the...

www.hobby-machinist.com

www.hobby-machinist.com