- Joined

- Dec 29, 2012

- Messages

- 394

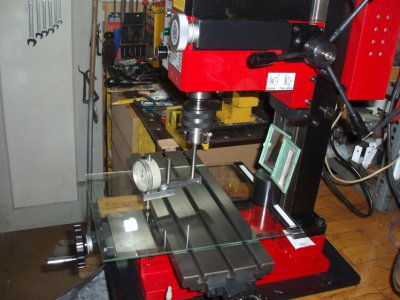

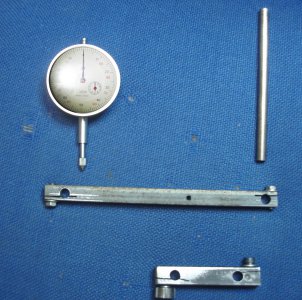

After cleaning and degreasing my new mill I made some measurements to test X and Y axis using simple tools:

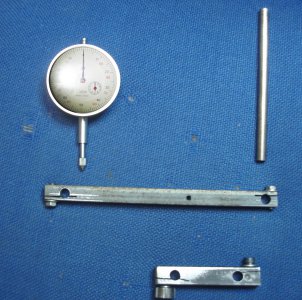

an indicator (metric 0,01mm/div)

an extension about 12,5 cm (5”) and

a small mirror to read the indicator when rotates and faces the mill column.

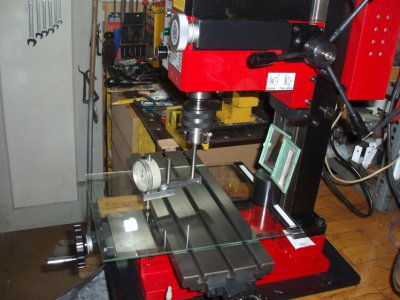

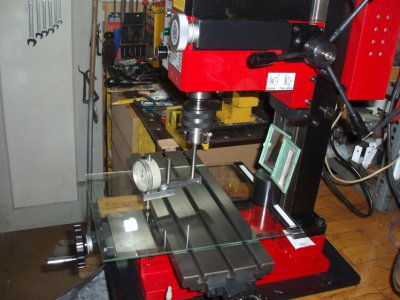

The procedure is quite simple. Place a surface plate on the mill table, put indicator in a collet (or in the drill chuck), zero it to a corner and then rotate it a full circle BY HAND writing down each corner reading.

To manage this procedure without a surface plate I used a piece of glass from an old scanner (as the flattest think in possession).

I found mill column to lean 0,2mm to the front and 0,4 mm to the left so I decided to shim the column.

Initial efforts using paper (0,06 mm thickness) failed miserably, so I looked for better and more robust shims.

Most convenient of all available materials was beer tin (nasty habits, I know) at a thickness 0,1 mm and kitchen aluminum foil at a thickness of 0,01mm.

After several trial and error settings I managed to make table stand vertical and the best readings I had were:

X axis 0,01 mm end to end

Y axis 0,02 mm end to end.

I’m quite happy with that and I can start use the mill now.

Petros

an indicator (metric 0,01mm/div)

an extension about 12,5 cm (5”) and

a small mirror to read the indicator when rotates and faces the mill column.

The procedure is quite simple. Place a surface plate on the mill table, put indicator in a collet (or in the drill chuck), zero it to a corner and then rotate it a full circle BY HAND writing down each corner reading.

To manage this procedure without a surface plate I used a piece of glass from an old scanner (as the flattest think in possession).

I found mill column to lean 0,2mm to the front and 0,4 mm to the left so I decided to shim the column.

Initial efforts using paper (0,06 mm thickness) failed miserably, so I looked for better and more robust shims.

Most convenient of all available materials was beer tin (nasty habits, I know) at a thickness 0,1 mm and kitchen aluminum foil at a thickness of 0,01mm.

After several trial and error settings I managed to make table stand vertical and the best readings I had were:

X axis 0,01 mm end to end

Y axis 0,02 mm end to end.

I’m quite happy with that and I can start use the mill now.

Petros