- Joined

- Feb 2, 2013

- Messages

- 3,622

in high school, i learned oxy/acetylene welding and brazing operations.

when i went to community college in the late 80's, i spent 2 years and a semester learning welding processes.

gtaw and smaw. i learned a ton of stuff from a master welder who ran the program.

i would use a mig welder at work, get off work drive to school,show up early to class, and learned smaw on monday,wed

learned gtaw tuesday,thursdays. i couldn't get enough :welding:.

needless to say i got a lot of welding in and became addicted to joining metal together.

i came across a process that's very old- carbon arc welding...

i have been intimate with a gouging torch may times, but never even considered carbon arc as a welding process.

come to find out that it was first discovered and used in 1800 and is effective on ferrous and non-ferrous metals.

DCEN (straight polarity) is used.

i then remember my welding teacher talking about brazing and welding with twin carbon arc on AC.

there was 1 half page explanation of the process in our textbook and i had forgotten all about it entirely.

i recently reread some of the textbooks and ran across some notes that i had taken on the subject.

the first thing that jumped out at me was the process was extremely effective for repairing cast iron, both as a welding process and a brazing process.:thinking:

i came to the sudden realization...

i never had the pleasure to twin carbon arc braze or weld anything:angry: this was a hurdle i had to jump,

here's why...

i recently found a deal on a complete vintage 1972 wards(century) 230 ac welder w/ a twin carbon arc torch set up complete with some electrodes .

i have an old school JET 370 power hacksaw that has some cast iron in need of repairing...:biggrin:

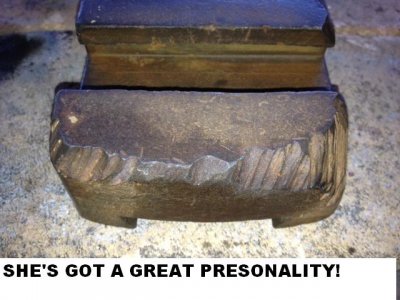

the miter clamping bolt goes into a cast iron clamping plate with poor threading...

i got lucky on one side i was able to put a stud into the clamp on one of the clamps, an easy fix.

as for the other clamp, i wasn't so lucky.

it was poorly drilled from the factory and not much of the thread profile remained.

a stud was out of the question for now...

i thought to myself, what an excellent opportunity.... to try a new old thing

i fired up my recently acquired shop oven(on casters) and preheated my damaged clamp to 300*F

i took out the Twin Carbon Arc Rig, slapped a couple 3/8" carbon rods cranked er' up to 90 amps and went to town on a brazing operation to fill up the hole in the cast iron. the process is slow , but, i was amazed that i didn't need flux on the brazing rod to get the puddle to stick. after a few minutes of brazing, BaddaBing ...

i put the casting on firebricks inside the oven to cool overnight.

i'll post more as i finish the repairs!

stay tuned for part 2

thanks for reading!

when i went to community college in the late 80's, i spent 2 years and a semester learning welding processes.

gtaw and smaw. i learned a ton of stuff from a master welder who ran the program.

i would use a mig welder at work, get off work drive to school,show up early to class, and learned smaw on monday,wed

learned gtaw tuesday,thursdays. i couldn't get enough :welding:.

needless to say i got a lot of welding in and became addicted to joining metal together.

i came across a process that's very old- carbon arc welding...

i have been intimate with a gouging torch may times, but never even considered carbon arc as a welding process.

come to find out that it was first discovered and used in 1800 and is effective on ferrous and non-ferrous metals.

DCEN (straight polarity) is used.

i then remember my welding teacher talking about brazing and welding with twin carbon arc on AC.

there was 1 half page explanation of the process in our textbook and i had forgotten all about it entirely.

i recently reread some of the textbooks and ran across some notes that i had taken on the subject.

the first thing that jumped out at me was the process was extremely effective for repairing cast iron, both as a welding process and a brazing process.:thinking:

i came to the sudden realization...

i never had the pleasure to twin carbon arc braze or weld anything:angry: this was a hurdle i had to jump,

here's why...

i recently found a deal on a complete vintage 1972 wards(century) 230 ac welder w/ a twin carbon arc torch set up complete with some electrodes .

i have an old school JET 370 power hacksaw that has some cast iron in need of repairing...:biggrin:

the miter clamping bolt goes into a cast iron clamping plate with poor threading...

i got lucky on one side i was able to put a stud into the clamp on one of the clamps, an easy fix.

as for the other clamp, i wasn't so lucky.

it was poorly drilled from the factory and not much of the thread profile remained.

a stud was out of the question for now...

i thought to myself, what an excellent opportunity.... to try a new old thing

i fired up my recently acquired shop oven(on casters) and preheated my damaged clamp to 300*F

i took out the Twin Carbon Arc Rig, slapped a couple 3/8" carbon rods cranked er' up to 90 amps and went to town on a brazing operation to fill up the hole in the cast iron. the process is slow , but, i was amazed that i didn't need flux on the brazing rod to get the puddle to stick. after a few minutes of brazing, BaddaBing ...

i put the casting on firebricks inside the oven to cool overnight.

i'll post more as i finish the repairs!

stay tuned for part 2

thanks for reading!

Last edited: