So, will a Dorian AXA tool holder fit any other AXA QCTP?

Yes they will physically fit the tool post but that doesn't always mean you will be able to use one of their tool holders.......

I have found one exception to the size rule and that is Dorian. All of their tool holders seem to have a larger range than normally expected.

That's Dorian for you, always trying to be innovative (a good thing) by constantly making changes (not always a good thing). This post may be a bit long so here it goes.

As far as I know, Aloris set the standard as they created the most known QCTP. I have a Dorian SQCTP, which I absolutely love over the others I have used/owned (Aloris, Armstrong, DTM, China, & PhaseII-China), but I follow Aloris' standards.

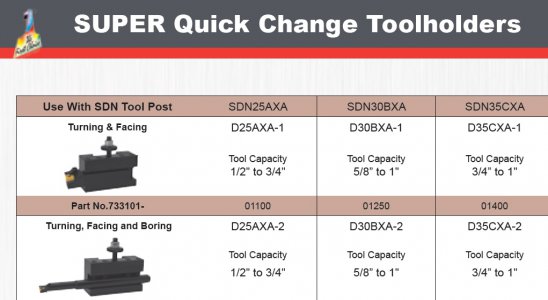

These are the following max tool capacities for each series' standard holders (I'll just cover the 3 common sizes):

AXA - 1/2"

BXA - 5/8"

CXA - 3/4"

Now Aloris, DTM, Dorian (probably others too) make oversized holders which step up 1 shank size. The Aloris oversized holders have the 1S designation at the end of their holders' p/ns. The following are the capacities for the oversized holders

AXA - 5/8"

BXA - 3/4"

CXA - 1"

Dorian on the other hand seems to change their tool holders every so often & without warning or changing p/ns. In the past Dorian tool holders followed the same standard. I have a BXA so let's talk BXA. So Dorian would make standard holders for BXA that held 5/8" max shanks & also made oversized holders that held 3/4" shanks. Then at some point the standard size holders p/ns were found in the oversized dimensions. And later changed again.

Dorian does not update/change their p/ns when they make a major change. The Dorian BXA SQCTP is SDN30BXA but so were their previous QCTPs. When I ordered my Dorian SCQTP, at the time there were still the older cam lock (that's cam lock, not piston) tool posts in stock at various vendors & is what I received.

Dorian Cam Lock QCTP

But what I wanted was their "SQCTP" wedge lock.

As you can see they have the same p/n, same red paint. Many vendors had no idea what I was talking about. Even called Dorian & their CS was confused, not until Dorian transfered me to one of their engineers was I able to finally talk to someone who knew what I was talking about. He was very helpful, contacted the distributor I was buying from & I was finally able to get the right one. The previous cam lock model had black paint, but same p/n, the latest SQCTP is no longer red, it's silver now, again same p/n.

The Dorian BXA standard holder p/n is D30BXA-1 (or 2 for v groove) which is 5/8" capacity, well was. The Dorian BXA oversized holder p/n is D30BXA-1-100 which is 3/4" capacity, again was. So when I bought a Dorian oversized holder D30BXA-1-100, I was surprised to find that it had a 1" capacity & not 3/4" as it used to be. Now I can't even find anyone selling the oversized D30BXA-1-100 anymore, no one has it in stock. Why?

So now the standard holder D30BXA-1 comes with a 1" capacity but it's not identical to the D30BXA-1-100 oversized holder.

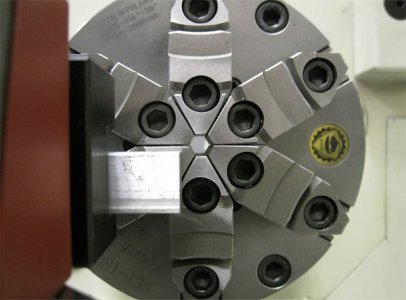

Here's a D30BXA-1 next to a D30BXA-1-100. Looks the same right? They aren't, look at the set screws placement.

The shank is 3/4"H x 1"W. As you can see the slot in the "standard" D30BXA-1 is not as deep as the oversized holder. The "standard" holder is only .6" deep & the oversized holder is 3/4" deep, no big deal though.

I like the tools to sit on the low end of my tool post, that way I can use largest shank tools (standard size) as well as smaller tools in my tool post. See how low the following tools sit?

5/8"

1/2"

3/8" (I rarely use smaller than 3/8", mostly 5/8" & 1/2")

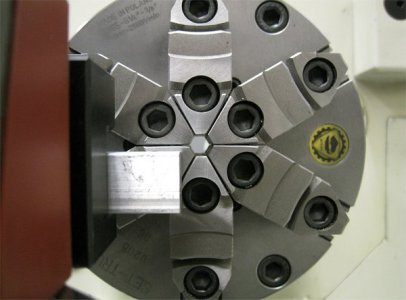

Now here's the Dorian 1" capacity holder sitting as low as it can go.

See how tall it is. Your lathe size (compound slide to spindle centerline height) vs tool post size determines whether or not you can use Dorian's extremely oversized holders max capacity. Generally turning tools have their cutting edge inline with the top surface of the shank, not always, but usually. With that in mind look at this.

1" in the Dorian 1" holder & the holder bottomed out. No way a 1" shank will reach centerline of the spindle.

3/4" in the Dorian 1" holder, now 3/4" would be able to reach centerline.

So unless your lathe is using a tool post that is on the small end for the lathe size, you most likely will not be able to use Dorian's max capacity on the ridiculously oversized holders. I think AXA is on the small side for my lathe but only then would I be able to use Dorian's max capacities. I rather not & stick with BXA.

Why they make it like that as a standard now beats the hell out of me but I don't like it. I don't like how their holders are inconsistently changing. I bet if you went out and bought a Dorian FTB tool post set right now you may not even received those 1" "standard" holders with the set as many vendors probably don't have them in stock yet.