- Joined

- Apr 21, 2013

- Messages

- 208

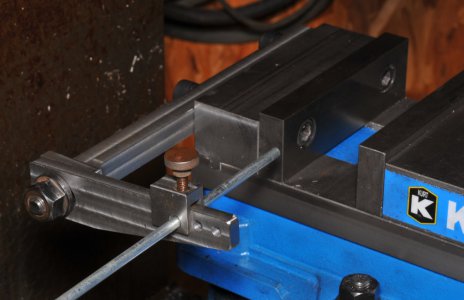

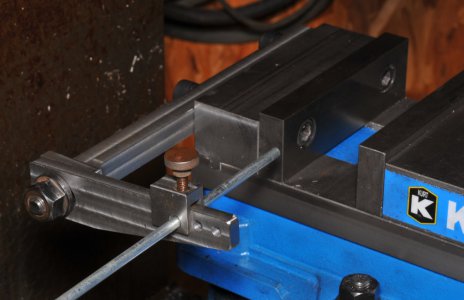

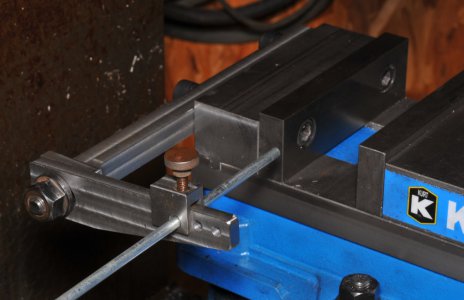

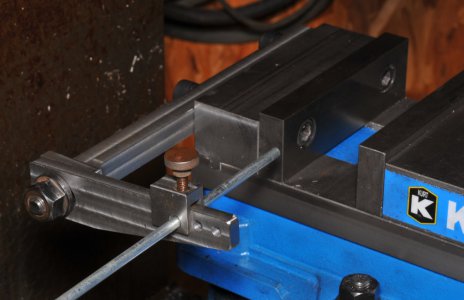

I'm very new into the machining world and this is one of my first projects. I built a vise stop last night for the Kurt vise that I picked up earlier this week. I thought I'd share some photos of the finished product.

Overall view

3/4" square back bar with .375 x 1.375 square end plate welded on and then machined square.

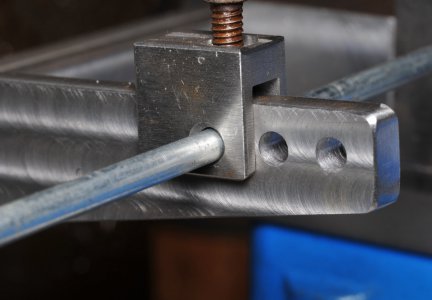

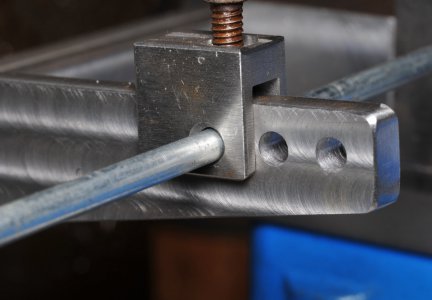

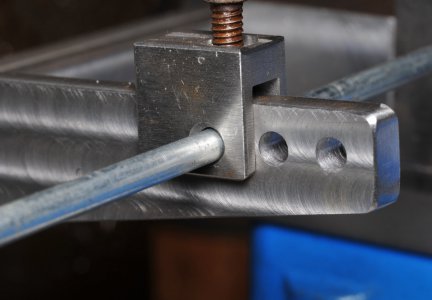

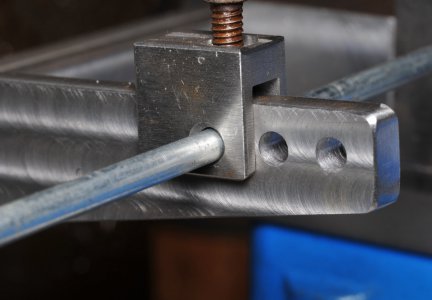

Adjustable stop detail

I used the same size bolt as my table hold-downs so I wouldn't have an additional wrench to find. I put the back bar in a 4-jaw chuck on my lathe to drill and thread the 1/2 x 13 bolt hole. (the stud is held in place with a set screw from below). The hole in the pivoting arm is elongated 3/8" in order to be able to set the stop anywhere within the 2" range that it has.

I used it tonight for another project and it works great.

Jack

Fort Loramie, Ohio

Overall view

3/4" square back bar with .375 x 1.375 square end plate welded on and then machined square.

Adjustable stop detail

I used the same size bolt as my table hold-downs so I wouldn't have an additional wrench to find. I put the back bar in a 4-jaw chuck on my lathe to drill and thread the 1/2 x 13 bolt hole. (the stud is held in place with a set screw from below). The hole in the pivoting arm is elongated 3/8" in order to be able to set the stop anywhere within the 2" range that it has.

I used it tonight for another project and it works great.

Jack

Fort Loramie, Ohio