- Joined

- Nov 7, 2019

- Messages

- 433

Alright so I've been on and off about wether I should make a thread about this, but it does have a fair few machining related projects.

As usual with my threads, there'll be a lot of photos.

I bought this car back in march 2019, the motor wouldn't run and the car itself was in pretty poor condition.

Let's start off with saying that my overall skillset at this time was quite lackluster so this is not a how-to-documentary...

Beyond changing brake pads and such, I've never really worked on cars before at this point.

This is the car a few days after I got it home, plugged in a charger almost instantly to try and recover the battery a bit.

The motor spins around but won't run, seller suspected the mechanical fuel pump.

The interior has definitely seen better days.

Cracked dash, cracked leather, ruined door cards, disgusting steering wheel, only the speedometer works and so on.

Someone has at some point in time replaced the electricals, not a single cable is color coded and it's all a big mess.

I spent a week or two on the wiring and motor to get it in running condition.

The fuel pump was shot, the carburettor had several seals that were beyond broken, 2 ignition cables were faulty, the ignition coil wasn't wired in correctly and so on ...

Eventually I got to the point where it would actually start and was just about driveable.

I added a temporary gauge cluster just so I could monitor the engine temps and such.

I drove it like this for just a few rides but quickly got tired of how it handled.

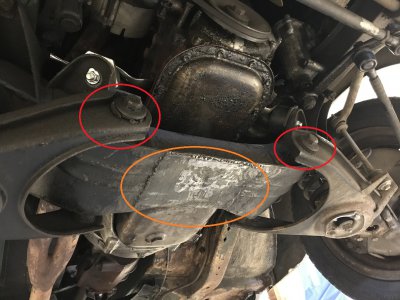

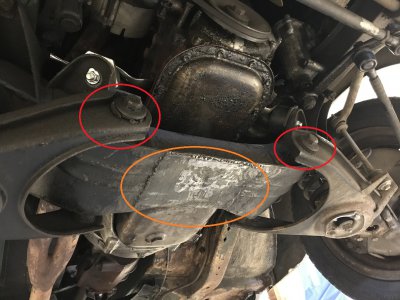

Further investigation proved that every single bushing in the frontend was pretty much destroyed along with the engine mounts.

You can also see the super suspicious 'repair' in the orange circle.

The gearbox also had it's own set of issues, you could only get 1st and 2nd gear to mesh if you were at a stand still and with the weak motor this made it horrible to drive at slower speeds.

I cleaned everything out thoroughly and replaced 3 syncros, gave it a new paintjob and some polish.

So about the bushings in the frontend.

I started tearing every little piece of the frontend just to make sure I had gone through everything.

Everything was so dirty that it was difficult to even find the bolts that held things together.

I built myself a sandblasting cabinet and went to town..

Part way through the process I realized that for the price of the original brake discs, I could get both calipers and brake discs from a newer volvos.

Not only are these more modern but they're ventilated and much beefier.

I started modeling and 3D-printing different brake discs from common volvos to check what offsets would work well.

I could probably have done this in CAD alone but with my limited experience I wanted the parts in hand to get a feel for fit and size.

I think I finally ended up with both disc and caliper from Volvo 240.

If you look closely you can see the double hole pattern in the 3D printed discs.

This is because the Amazon/13134 hubs have a 5x114.3 pattern whilst the more modern stuff has 5x108.

To be continued.

As usual with my threads, there'll be a lot of photos.

I bought this car back in march 2019, the motor wouldn't run and the car itself was in pretty poor condition.

Let's start off with saying that my overall skillset at this time was quite lackluster so this is not a how-to-documentary...

Beyond changing brake pads and such, I've never really worked on cars before at this point.

This is the car a few days after I got it home, plugged in a charger almost instantly to try and recover the battery a bit.

The motor spins around but won't run, seller suspected the mechanical fuel pump.

The interior has definitely seen better days.

Cracked dash, cracked leather, ruined door cards, disgusting steering wheel, only the speedometer works and so on.

Someone has at some point in time replaced the electricals, not a single cable is color coded and it's all a big mess.

I spent a week or two on the wiring and motor to get it in running condition.

The fuel pump was shot, the carburettor had several seals that were beyond broken, 2 ignition cables were faulty, the ignition coil wasn't wired in correctly and so on ...

Eventually I got to the point where it would actually start and was just about driveable.

I added a temporary gauge cluster just so I could monitor the engine temps and such.

I drove it like this for just a few rides but quickly got tired of how it handled.

Further investigation proved that every single bushing in the frontend was pretty much destroyed along with the engine mounts.

You can also see the super suspicious 'repair' in the orange circle.

The gearbox also had it's own set of issues, you could only get 1st and 2nd gear to mesh if you were at a stand still and with the weak motor this made it horrible to drive at slower speeds.

I cleaned everything out thoroughly and replaced 3 syncros, gave it a new paintjob and some polish.

So about the bushings in the frontend.

I started tearing every little piece of the frontend just to make sure I had gone through everything.

Everything was so dirty that it was difficult to even find the bolts that held things together.

I built myself a sandblasting cabinet and went to town..

Part way through the process I realized that for the price of the original brake discs, I could get both calipers and brake discs from a newer volvos.

Not only are these more modern but they're ventilated and much beefier.

I started modeling and 3D-printing different brake discs from common volvos to check what offsets would work well.

I could probably have done this in CAD alone but with my limited experience I wanted the parts in hand to get a feel for fit and size.

I think I finally ended up with both disc and caliper from Volvo 240.

If you look closely you can see the double hole pattern in the 3D printed discs.

This is because the Amazon/13134 hubs have a 5x114.3 pattern whilst the more modern stuff has 5x108.

To be continued.