-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What should I use...Home made Tap

- Thread starter MattM

- Start date

- Joined

- Dec 27, 2014

- Messages

- 4,055

A1 W1 or O1 drill rod. they are (respectively) air, water and oil hardenable.

Tried the HW store. More than a few. None have them.

I can buy this from Midway but they want about $25.00 for it plus shipping.

Making an adapter for a suppressor. Yes, I know I can buy one but I want to make one and it requires a 1/2x28 tap.

I know this is stupid but I want to do it.

I can buy this from Midway but they want about $25.00 for it plus shipping.

Making an adapter for a suppressor. Yes, I know I can buy one but I want to make one and it requires a 1/2x28 tap.

I know this is stupid but I want to do it.

- Joined

- May 4, 2015

- Messages

- 3,583

Why not cut the threads on your lathe? It's not that hard and fine threads are easier to cut. At least I think so. Or try watching eBay there on there I bet a China one even for about $8.00 delivered. get the die too.

- Joined

- May 4, 2015

- Messages

- 3,583

I looked on eBay for about $10.00 you can get a Bosch brand tap and an Irwin die in 1/2"-20

Why not cut the threads on your lathe? It's not that hard and fine threads are easier to cut. At least I think so. Or try watching eBay there on there I bet a China one even for about $8.00 delivered. get the die too.

Internal blind threads that small would be very difficult to cut, at least for me.

I know I can buy one and that certainly makes more sense than making one. The real reason is: I have two friends, both highly skilled retired machinists, and they are telling me I can't do it. Next time we all take lunch I want to place my homemade tap and the threader adapter on the table and see their reaction. Maybe I'll get a free lunch.

- Joined

- Nov 23, 2014

- Messages

- 2,606

Good luck with the project! Nothing like making an "expert" eat crow! I think taps usually have a little relief behind the cutting edge, not just straight turned/threaded. Like mentioned above, use O1, W1 or A2. Drill rod would be my choice since I have a good selection in a lot of diameters.

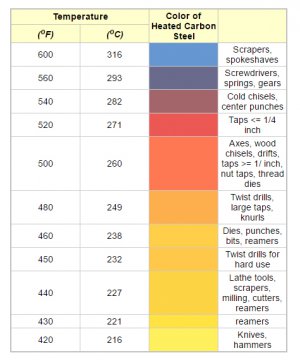

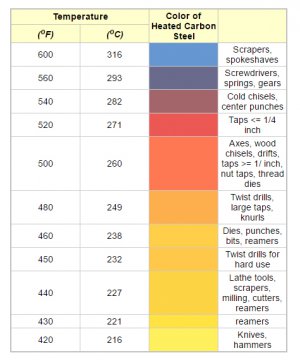

I'd probably cut the threads on the lathe so you could make it a little on the large size. I'm thinking running a die over the drill rod would make you a tap, but wouldn't be deep enough of a cut to easily run hardware store bolts through its tapped holes. Go to the mill after threading and cut flutes with a ball end mill. If you're using an indexer in the mill (i.e. rotary table with a chuck, spin indexer, dividing head as opposed to a square 5-C collet block) you could relieve the back of the threads on the mill by going just past the lead edge and dust off a few thousandths. Or maybe just carefully grind some relief by hand. Harden with a torch and temper to 500 F per the chart attached (downloaded from somewhere on line).

Make sure to include a couple pictures of your buddies jaws setting a gap!

Bruce

I'd probably cut the threads on the lathe so you could make it a little on the large size. I'm thinking running a die over the drill rod would make you a tap, but wouldn't be deep enough of a cut to easily run hardware store bolts through its tapped holes. Go to the mill after threading and cut flutes with a ball end mill. If you're using an indexer in the mill (i.e. rotary table with a chuck, spin indexer, dividing head as opposed to a square 5-C collet block) you could relieve the back of the threads on the mill by going just past the lead edge and dust off a few thousandths. Or maybe just carefully grind some relief by hand. Harden with a torch and temper to 500 F per the chart attached (downloaded from somewhere on line).

Make sure to include a couple pictures of your buddies jaws setting a gap!

Bruce

- Joined

- Dec 12, 2012

- Messages

- 109

I know exactly how you feel and it's not stupid. As soon as someone tells me I can't do something it simply fuels the fire and I become more determined.

Some considerations that pop into my head:

One time use only? What is the part material hardness?

Could you start with a 1/2"-28 bolt and cut the flutes? Obviously the bolt material isn't as hard as O1, W1, A2, etc, but if you're only using it once and the part material is relatively soft, you might be able to get away with it?

If you want to do it right than I'd say Bruce has some good advice!

I just goolged "making taps" (kind of feel guilty, like I cheated for some reason) and a thread (ha!) on another forum popped up. I hope I don't rub anyone the wrong way by posting this, if I do let me know and I'll remove it:

http://www.practicalmachinist.com/vb/general/making-taps-187694/

Some considerations that pop into my head:

One time use only? What is the part material hardness?

Could you start with a 1/2"-28 bolt and cut the flutes? Obviously the bolt material isn't as hard as O1, W1, A2, etc, but if you're only using it once and the part material is relatively soft, you might be able to get away with it?

If you want to do it right than I'd say Bruce has some good advice!

I just goolged "making taps" (kind of feel guilty, like I cheated for some reason) and a thread (ha!) on another forum popped up. I hope I don't rub anyone the wrong way by posting this, if I do let me know and I'll remove it:

http://www.practicalmachinist.com/vb/general/making-taps-187694/