- Joined

- Jan 7, 2014

- Messages

- 113

Hi All,

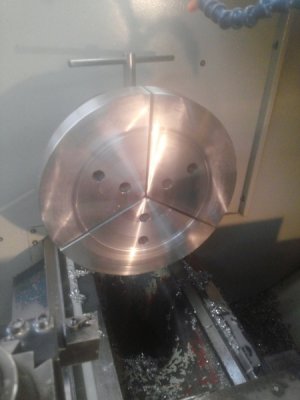

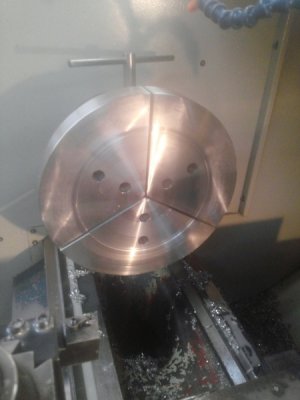

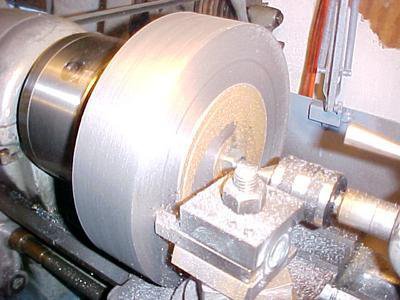

I am making an adapter to mount a Bridgeport head on a famco mill column. I have 3 1" steel plates that I need to machine to make the adapter. I thought that my friends 12" Clausing was going to be able to do the job but I found that he did not have a 4 jaw and the 3 jaw would not grab it. Anyone know off hand what size chuck would be needed to grab a 8.125 dia? I am in the Mpls/St Paul MN area if anyone is interested in helping a fella out.

Thanks,

Ben

I am making an adapter to mount a Bridgeport head on a famco mill column. I have 3 1" steel plates that I need to machine to make the adapter. I thought that my friends 12" Clausing was going to be able to do the job but I found that he did not have a 4 jaw and the 3 jaw would not grab it. Anyone know off hand what size chuck would be needed to grab a 8.125 dia? I am in the Mpls/St Paul MN area if anyone is interested in helping a fella out.

Thanks,

Ben